Unit 2a. General functions, characteristics and classification of LAB (starter) cultures

Lactic Acid Bacteria (LAB) are gram positive, non-spore forming bacteria that can be shaped as rod (bacillus) (e.g lactobacilli) and cocci (e.g. streptococci and lactococci).

They are used not only in dairy but in the manufacture of fermented meats, olives, vegetables. They are used to ensure safety and to develop flavour in many products. In cheese, LAB strains are added to start the fermentation, therefore these are known as starter cultures.

The Lactic Acid Bacteria (LAB) family is firstly subdivided into of a number of species including bacilli (rods) or cocci (round/chains). These include the Lactobacilli and Lactococci. The next sub-division is the subspecies. So for Lactobacilli it would be for example Lactobacillus delbruecki subsp. bulgaricus (we know it as a Lb. bulgaricus) or Lactobacillus delbrueckii subsp. helveticus (known as Lb. helveticus). The main subspecies groupings include Lactococcus lactis subsp. cremoris (or Lactococcus cremoris) and Lactococcus lactis subsp. lactis (or Lactococcus lactis). Subspecies sometimes cab be divided into biovars which differ physiologically or biochemically for example Lactococcus lactis subsp. lactis biovar diacetylactis.

The final division of the subspecies is into individual strains each which have their own characteristics which may be useful for cheese manufacture. These strains are often described as a combination of letters and numerals e.g Lc lactis subsp. cremoris AM2 (often shortened to Lc. cremoris AM2), Lactobacillus delbrueckii subsp. helveticus 4571 (often shortened to Lb. helveticus 4571) or Lactococcus lactis subsp. lactis biovar diacetylactis FM03P.

So there are many different strains within each species and subspecies, some of which are Starter Lactic Acid Bacteria (SLAB) and some of which are Non-Starter Lactic Acid Bacteria.

The main families of starter LAB are Lactococci, Leuconostoc, Lactobacillus and Steptococcus. Other LAB are not added as starter cultures in dairy, but may be in the milk and may grow during ripening e.g. Pediococcus, which is used as starter in salami. Other LAB can be added as probiotics, such as Bifidobacterium. LAB can be used also as secondary cultures; a common one would be Brevibacterium, which contributes to the red smear on washed-rind varieties, such as Oka. These highly aromatic and flavourful varieties differ according to growth conditions such as humidity, pH, oxygen, salt, and temperature.

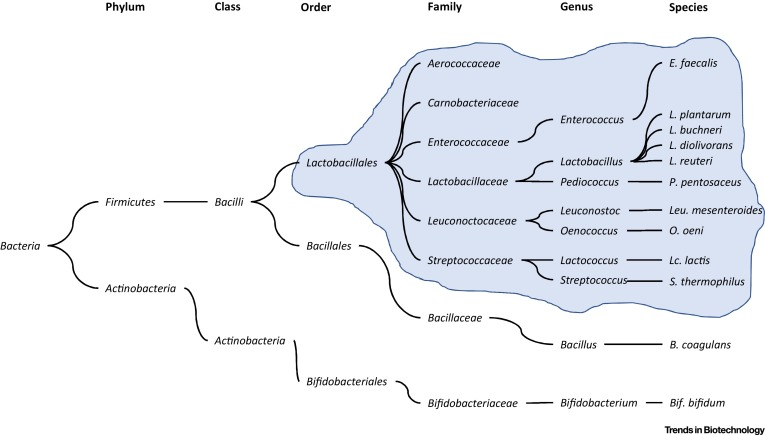

The following figure, shows the family tree of LAB. Please note the term Bacilli (upper case B) after firmicutes, Bacilli is the class where Lactobacillates belong to. This class name is similar to the term bacilli (lower case b) which is the plural for bacillus, the name assigned to rod shaped bacteria.

Famil Family tree of LAB (Sauer et al., (2017))

Family tree of LAB (Sauer et al., (2017))

Lactic acid bacteria are classified according to their optimum growth temperature and principal metabolites. Mesophilic LAB have optimum growth near 30°C and a growth range of 20 – 40°C. On the other hand, thermophilic LAB have optimum growth between 40 and 46°C, and a growth range of 45 – 60°C. According to the fermentation end-products, LAB are called homofermenters if the fermentation leads to lactic acid only (from lactose), and are called heterofermenters if lactose fermentation generates lactic acid and other products, such as propionate, acetate and C02. Heterofermenters can also metabolize citrate to produce diacetyl, acetoin and C02.

Lactic acid bacteria are a big group of families and trying to remember even the common ones is a little daunting. The following diagram (Figure 2a.1) attempts to classify the main LAB. Click on the “question mark” signs to learn about the different groups.

Figure 2a.1. General classification of LAB (considering only temperature and end-product characteristics)

Not all lactic acid (LA) producing bacteria make good starters. Good starter cultures need to have:

- Consistent acid production

- Significant bacteriophage resistance

- Ability to survive cheese cooking temperatures (38.5°C). Remember higher cooking temperatures require thermophilic cultures.

- Salt tolerance (2.7% salt added to Cheddar = ~5.5 % salt in moisture)

- Low counts of spoilage bacteria, yeasts and moulds, and, hopefully, no pathogenic bacteria.

- Compatibility with other strains in the mix

- Capacity to inhibit non desirable bacteria via competition or production of bacteriocins

- Desired flavour production e.g., non-bitter

- Rapid death rate, autolysis, so there is good enzyme release for ripening.

In the CMC1- Introduction to Cheese Making Technology Course we learned that milk is a perfect growth media for microorganisms, especially for LAB for many reasons, including the fact that it contains all nutrients that LAB requires for growth. That is why during cheese production, inoculation of LAB to 106/ml results in further growth to 108 – 109/g of cheese at the end of production.

The most important requirements for LAB to grow are carbohydrate and nitrogen sources in milk. Carbohydrates in milk are mainly lactose. LAB bacteria, unlike some people have the capacity to convert lactose to LA (homofermenters), or LA plus other substances (heterofermenters). Nitrogen is found in caseins, whey proteins, peptides (protein fragments) and amino acids. To grow well in milk, LAB need proteinases/peptidases to break down proteins to peptides and smaller nitrogenous compounds. LAB can only use nitrogen or small peptides to grow, but the small peptides and free nitrogen originally present in milk would only be enough to produce a final LAB cell density of 2%. The rest of the growth needed happens because of the proteinase system which is absolutely necessary for culture growth and cheese production! In other words, LAB must have their own protease systems or they must borrow nitrogen produced by other bacteria. Of course, culture selection needs to keep nitrogen needs in mind.

Functions of Starter Cultures

In Unit 1 we learned that cultures have specific functions in cheese making. The following list identifies a few of many properties that may be required for particular varieties.

- Acid production within a specified time period, for example Cheddar Cheese = 4.5 hours to acidify milk from ~pH 6.6 to ~5.2.

- Flavour production in final product, e.g “savoury” aged Cheddar cheese. This is possible thanks to enzymes in the cultures breakdown of the caseins and fats to generate flavourful peptides, amino acids and short chain fatty acids all of which are important for mature Cheddar flavour and any ripened cheese.

- Ensure Safety by inhibition of undesirable organisms, through colonization, pH reduction, or bacteriocin production.

- Texture effects, such as gas holes in Swiss cheese, and viscous yogurts made with ‘ropy’ strains of LAB that produce exopolysaccharides (EPS)

- Proteolytic properties

Acid Production

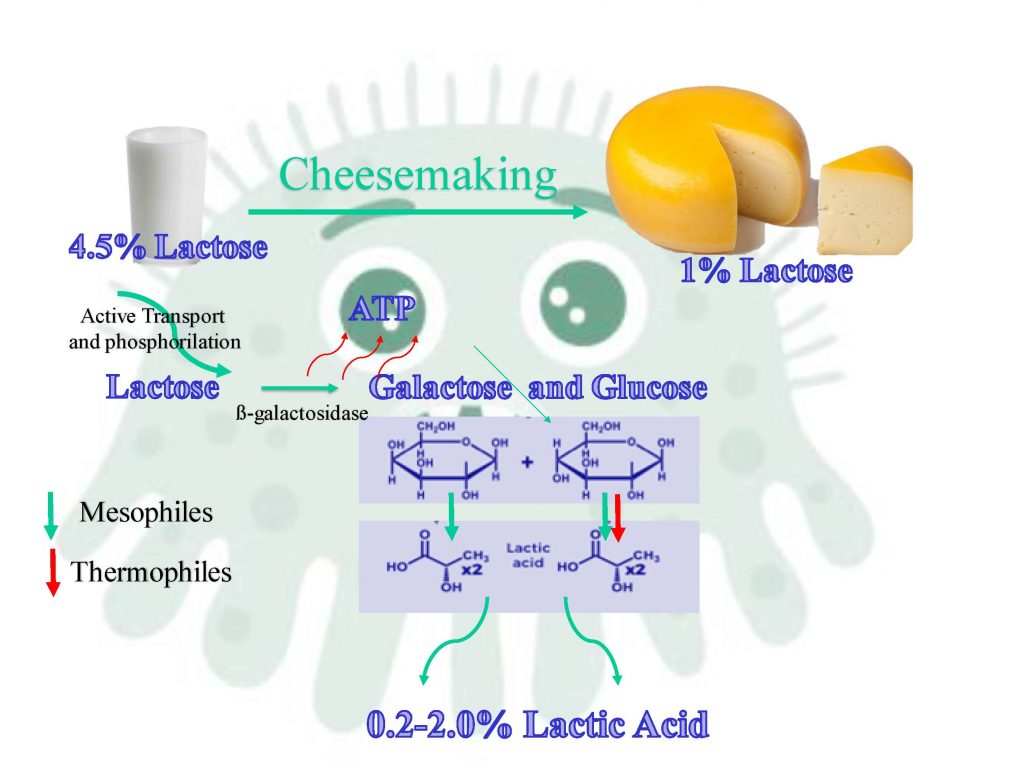

Figure 2a.2. Production of Lactic Acid by SLAB during cheese making.

Acid production is the major contribution required by starter bacteria during vat operations. LAB ferment lactose in milk to use it as a source of energy. The diagram above (Figure 2a.2.) helps explain the process. Milk contains about 4.5% of lactose. This lactose enters the bacterial cell by active transportation and phosphorylation so that the LAB can use it. The enzyme ß-galactosidase breaks down the lactose into galactose and glucose, while releasing ATP. Both glucose and galactose may be fermented to LA but some thermophilic cultures are only able to produce LA from glucose and not galactose (potentially leaving residual galactose in the cheese). At the end of cheese making (depending on the cheese), residual lactose is around 1%, often mostly as galactose, while the amount of lactic acid, depending on many factors, ranges, between 0.5 to 2% and commonly around 1%.

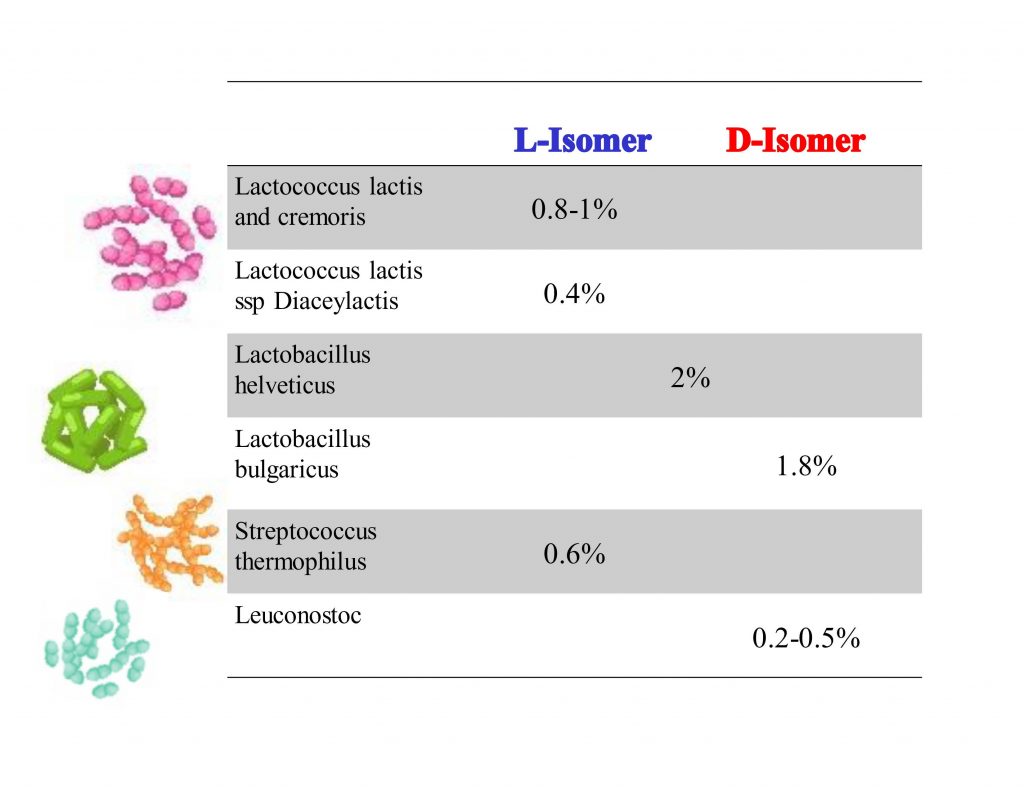

An important property of LA is that, like many biological molecules, it exists in two stereoisomers, called L- and D-Lactic Acid. These two isomers are identical except they are mirror images of each other. That means they may participate differently in chemical and biochemical reactions in the same way that two gloves appear identical, but you can’t put the right glove on your left hand. LAB produce LA mainly in the L-form, but some produce lactic acid in the D form. Table 2a.1 indicates production of D and L isomers by different LAB. D-Lactic acid, -but not L-Lactic acid- forms white crystals that appear on the surface and sometimes in the interior of many cheeses, especially aged varieties.

Table 2a.1. Content of L and D Lactate produced by different LAB.

Note that some starters like Leuconostoc produce only one isomer form, while others like Lactobacillus produce a combination of both isomers (in this case 2% of a mix of L and D-isomers).

Why L and D are important?

- L-lactate is more soluble than D-lactate particularly at cold temperatures, therefore D-forms of lactate can crystallize into calcium lactate crystals that forms a white precipitate on the surface of many cheeses, especially aged cheese. Customers often mistake the precipitate for mold. Calcium lactate on the surface of cheese can be minimized by a smooth cheese surface (without dimples) and a tight wrap that prevents collection of water droplets on the surface.

- Also note that some NSLAB can racemize (convert) L-Lactate to D-lactate, especially at warmer temperatures. Racemize refers to the tendency of D and L forms to move towards equilibrium. In this case racemization is encouraged by enzymes produced by some NSLAB.

- We will discuss L and D lactate more in other units.

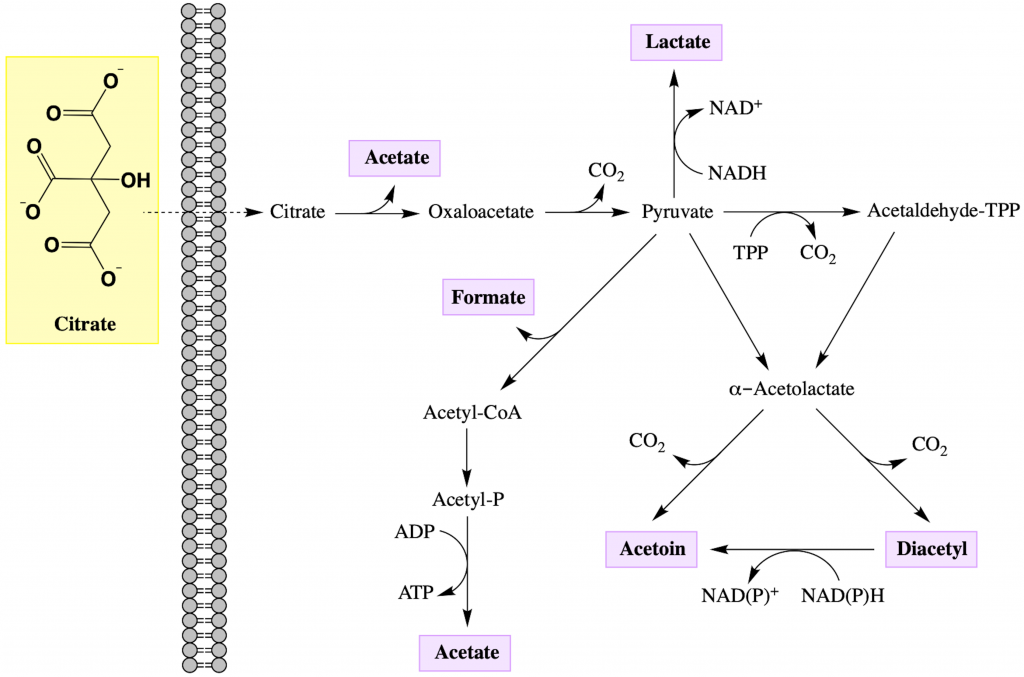

Citric Acid Fermentation

Some of the mesophilic starter bacteria (not the thermophiles) can utilize citrate in the milk as a carbon source for growth, for example:

- Lactococcus lactis subsp. diacelylactis.

- Leuconostoc spp.

- Citrate positive lactococci (Cit +)

These LAB can generate CO2, acetoin, and diacetyl (buttery aroma) and also acetate (Figure 2a.2). This type of LAB is added for gas hole (“eyes”) production in Dutch cheeses (e.g Edam) and added for aroma in lactic butter, quark, cultured buttermilk, etc.

Figure 2a.2. Citrate fermentation by LAB

Factors that affect acidification

Acid production mainly reflects growth of the bacterial strain. Acidification is affected by:

References:

Sauer, Michael, Russmayer, Hannes, Grabherr, Reingard, Peterbauer, Clemens K, Marx, Hans. 2017. The Efficient Clade: Lactic Acid Bacteria for Industrial Chemical Production. Trends in Biotechnology (35) 8.

A group of Gram-positive bacteria, non-respiring, non-spore-forming, (cocci or rods) which produce lactic acid as the major end product of their metabolism

Cultures: a prepared inocula of bacteria, yeasts or moulds that are added to milk in different stages of processing

cultures that are added to develop acidity and some main by-products (e.g. CO2)

Cultures that, more than producing acid, promote ripening

Enzymes that break proteins and peptides into smaller peptides and aminoacids

Adenosine triphosphate is an organic compound that provides energy to drive many essential processes in living cells.

molecules that have the exact molecular formula but differ in the direction of one of its components, for example in lactic acid they differ in the position of a particular OH group.