Unit 3a. Non-Starter Lactic Acid Bacteria

NSLAB are a group of adventitious bacteria which enter the cheesemaking process and grow during ripening.

Why are NSLAB so important?

NSLAB predominate the microflora of ripening cheese, they can make a cheese very unique and create two very different cheeses even if the process that created them was very similar. NSLAB are generally not deliberately added into cheese except when added as adjuncts but may enter the cheese making process from a number of sources. They grow slowly in milk and throughout cheese ripening and do not generate significant amounts of lactic acid during cheese manufacture

NSLAB mainly consist of mesophilic lactobacilli (mainly) and pediococci (occasionally), but can sometimes include Enterococcus or Leuconsotoc spp.

Most NSLAB lactobacilli are facultative heterofermenters (FHL) and are capable of producing a range of fermentation end products

Main Lactobacillus spp. found as NSLAB in cheese include:

- Facultative heterofermenters; FHL NSLAB:

- Lactobacillus casei: Lactobacillus casei has also been classified into both Lb. casei and Lb. paracasei. Lactobacillus paracasei is the most prevalent strain isolated from cheese.

- Lb. plantarum

- Lb. curvatus

- Lb. wasatchensis

- Obligate heterofermenter NSLAB:

- Lactobacillus brevis, an obligate heterofermenter, has also been detected but in lower populations

FHL characteristics

- Can hydrolyze lactose to end products including CO2, acetate, ethanol, and lactic acid

- Can generate both L- and D- forms of Lactate

- Most do not ferment citrate on their own, but can in the presence of a sugar, e.g. glucose, galactose or lactose.

- Generally grow poorly in milk and so most do not coagulate milk.

Sources of NSLAB

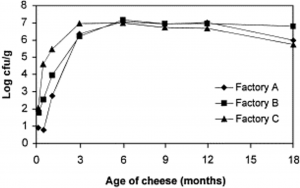

NSLAB primarily enter cheese via milk, both raw and pasteurized. But raw milk will have a more complex and abundant mix of NSLAB. Many of the FHL can survive pasteurization. Also, NSLAB have been found all over cheese plant including drains, floors, cheese vats, cheese moulds, packing machines and also as biofilms on above (Figure 3a.1). Evidence suggests the individual cheese plants may have their own particular NSLAB microflora. Known as “House” microflora.

NSLAB: Growth Substrates in Cheese

NSLAB require amino acids and proteins for growth. They can use free amino acids in cheese especially arginine. While starter cultures (SLAB) depend on lactose to grow, NSLAB in addition to lactose, may also use other energy sources, including:

- Sugars derived from cell walls and from DNA and RNA of lysed SLAB cells. This is called cannibalism.

- Sugars from the milk fat globule membrane (MFGM)

- Certain free fatty acids

NSLAB: Growth in cheese

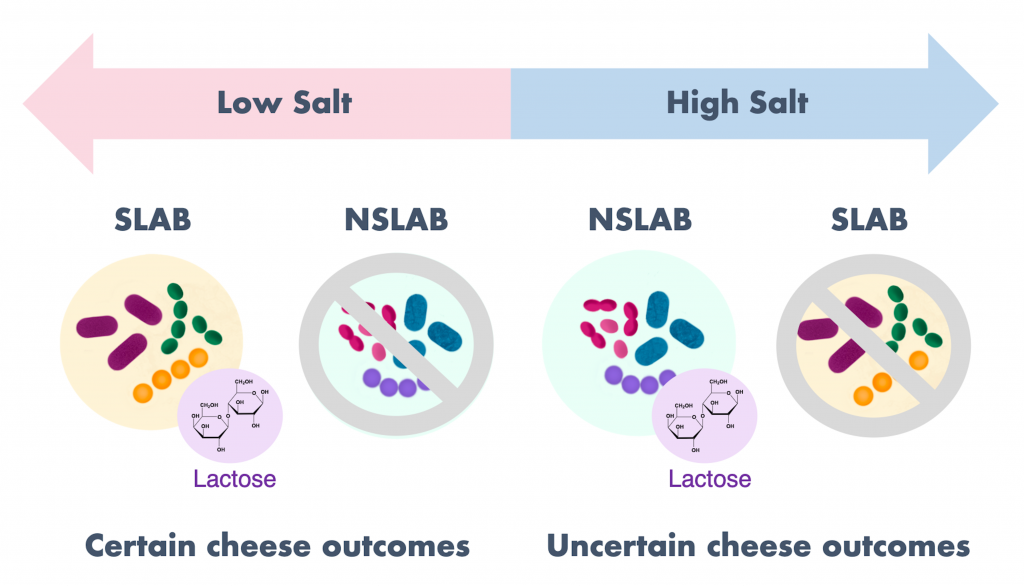

NSLAB compete with SLAB for residual lactose (~1%) and is influenced by salt content of cheese (Figure 3a.2). As a general rule:

- High salt: results in SLAB inhibition causing high or prolonged residual lactose. That allows for NSLAB use of the residual lactose = uncertain cheese quality outcome

- Low salt = More rapid use of lactose by SLAB during cheese making and more rapid use of the residual lactose by SLAB. during ripening. This reduces NSLAB growth resulting in more certain cheese quality outcomes.

- Increasing ripening temperature also accelerates NSLAB growth, but the final numbers are similar irrespective of temperature

- Autolytic properties of starters may influence NSLAB growth rate

Figure 3a.2. Effects of salt on SLAB and NSLAB growth in cheese

NSLAB in Cheese During Ripening

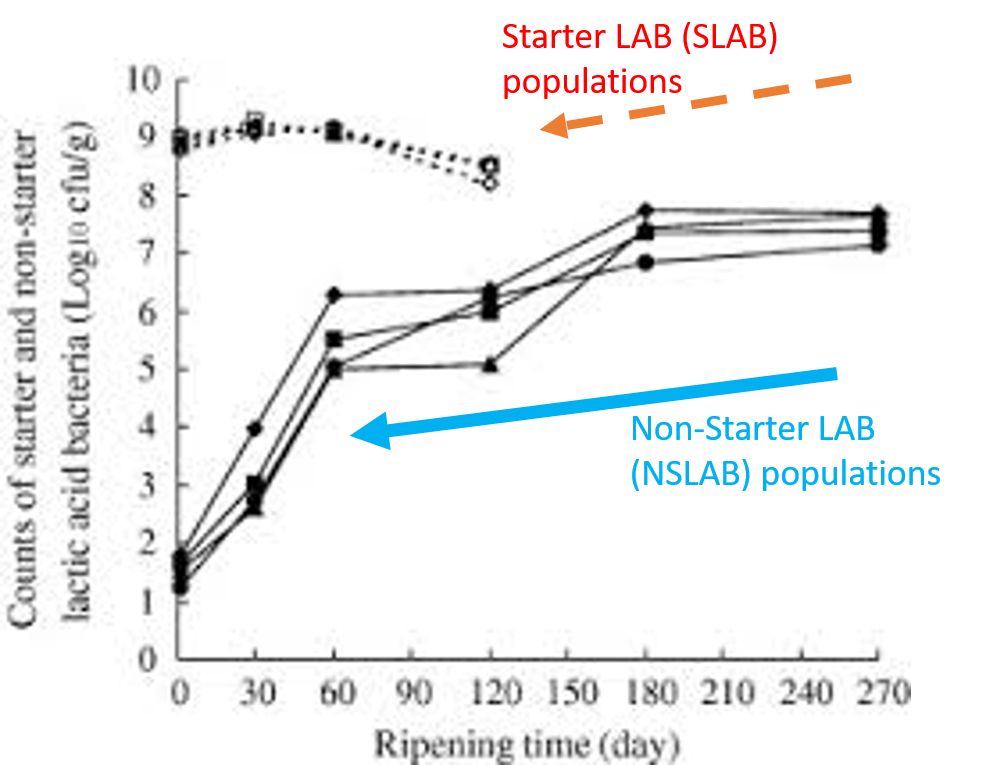

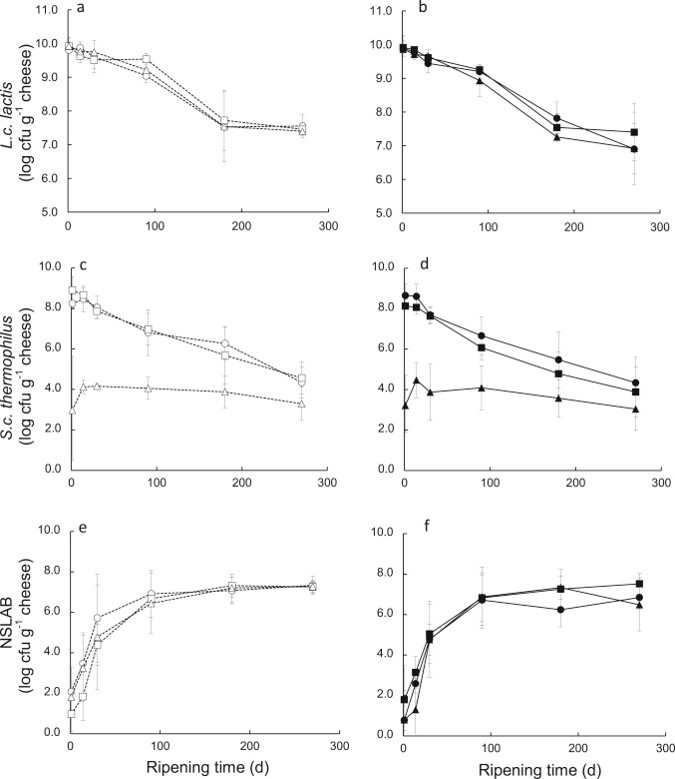

Starter Bacteria are often said to die off quickly during ripening. In fact SLAB dominant for the first 8 weeks, and then start to autolyse (die) at different rates, but generally quite slowly and substantial populations of SLAB persist to the end of ripening. In particular, Lc. lactis subsp. lactis strains are unaffected by cooking temperature and may persist for long periods during ripening. On the other hand, numbers of Lactococcus lactis subsp. cremoris are reduced substantially during cooking. Overall, most of SLAB growth occurs within the first 24h of cheese making, the population persists for a few weeks, and then starts to decay (not die off) (Figure 3a.3).

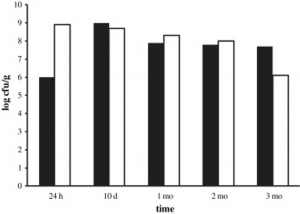

- Non-starter Lactic Acid Bacteria (NSLAB): Enter the cheese from process (survive pasteurisation, present in plant, added as adjunct), grow from day 1 ~102 CFU/g to 107-109 CFU/g beyond 8 weeks ripening. Being the dominant group at the end of ripening for many cheese varieties (Figure 3a.4)

Figure 3a.3. NSLAB in Cheese During Ripening (Rynne et al., 2007)

Fig 3.a.3 shows the dynamics of both starter (SLAB) and Non-starters (NSLAB) during cheese ripening. SLAB reach highest numbers in curd on day 1 at ~106 – 109 CFU/g and decline at differing rates thereafter. In contrast, NSLAB have low numbers at day 1 (~102 CFU/g) and then they continue to increase over ripening to become the dominant microflora at the later stages of ripening (107 – 109 CFU/g). NSLAB grow on the residual lactose, peptides produced by NSLAB and even on dead SLAB cells! Every cheese plant will have its own HOUSE FLORA of NSLAB which will contaminate the cheese during processing so not all NSLAB strains/species are the same in each cheese!

Figure 3a.4. Evolution of SLAB (white column) and NSLAB (black column) during ripening of Puzzone di Moena cheese (Settanni and Moschetti, 2010)

Exercise: Analyze the data in these two graphs. What conclusions are obvious?

NSLAB do not grow well in milk due to their scarce proteolytic activities (remember there is not enough free nitrogen and small peptides in milk for NSLAB to grow), and the level of residual lactose in cheese is almost fully depleted within a few days of ripening. Lack of lactose together with low pH values (~4.8–5.3), NaCl (1–3%), low moisture (~45–25%) and temperature (~8–12°C), besides microbial competition, make the cheese environment very hostile, and lactobacilli adaptation varies depending on different species and strains.

Because of lactose depletion, NSLAB had to adapt to diverse energy sources. Free fatty acids (FFA), peptides and free amino acids (FAA), and ribose released from lysed cells are the main nutrients for NSLAB. That is, it is the metabolism of SLAB and their death which allow NSLAB to grow.

Going back to the raw milk issue, let’s take a look at Figure 3a.5. Note that NSLAB populations (squares) are always higher at day 0 in raw milk. The higher the temperature (filled figures) the faster the growth rate. But at the end of the ripening period the populations of NSLAB are higher in raw milk cheese, but the gap between populations in raw and pasteurized milk decreases by the end of ripening.

Figure 3a.5. Growth of NSLAB in Cheddar cheese made from raw (□, ■) or pasteurized (○, •) milk and ripened at 1°C (○, □) or 8°C (•, ■) (Rehman et al., 2000)

Table 3a. 1. Attributes and Defects of NSLAB

| Atrribute | Defect | |

|---|---|---|

| Racemisation of L-lactate to D-lactate and calcium-D-Lactate crystals | Some desirable crystals in "Vintage" cheddar cheese | Create textures (crystals) in new varieties. Sometimes white spots on cheese surface taken as mould growth. Lb curvatus particularly associated with it |

| NSLAB can also convert D-lactate to acetate and CO2 | Growth of Lactobacillus wasatchensis associated with gas production and flavour defects in Cheddar cheese | Late gas can produce important economic losses, with cheese showing undesirable eyes, cracks and even explode, "blown packs” slits or “openness”, Causes downgrading or cutting losses of 10-50% due to crumbling. Growth of Lactobacillus wasatchensis and Lactobacillus brevis associated with gas production and flavour defects in Cheddar cheese. Lb wasatchensis is present in cheese as a slow growing NSLAB strain and when present in high numbers is associated with late gas production. It can be present in the initial milk but not be detected. “Late gas” production in Swiss cheese from 4-6 months in ripening |

| May provide additional source of enzymes for proteolysis, and undertake metabolisms of free amino acids | May contribute to desirable flavours and aroma | May result in bitterness and rotten aromas. Better controlled by secondary culture. |

| Might contribute to Biogenic Amines or other components | Some NSLAB have been associated with beneficial flavour and are added back as adjuncts or as probiotics, e.g Lactobacillus rhamnosus | Biogenic Amines: Carcinogenic and potentially toxic. e.g Histamine at 20 mg/kg can elicit an adverse response. Arises from activity of amino acid decarboxylase present in certain strains of Lb casei, Lb curvatus, Lb bulgaricus |

Activity of NSLAB in Cheese Ripening

Now we know that NSLAB can be viewed as another process variable, which can influence ripening outcomes either positively or negatively. Hence the technological approach has been to either:

- Reduce the numbers of NSLAB via control of the cheese process including milk quality, hygiene, CIP and low temperature ripening; or,

- To select beneficial NSLAB and add them back to improve cheese flavour, known as adjunct NSLAB

Positive flavour attributes

For an adjunct culture to provide good characteristics to cheese it must not interfere with acidification, cause no flavour or textural defects, improve flavour and overall quality, and maintain high population densities from the time of their addition. Data is variable on use of NSLAB as adjuncts; so not much info to start with

Negative ripening effects

One particular NSLAB strain Lb. wasatchensis has been implicated in “gassy” defects in Cheddar cheese, this NSLAB:

- Is visible as “blown packs” slits or “openness” found beyond 3 months of ripening, called late blowing defect

- Causes downgrading or cutting losses of 10-50% due to crumbling

- Novel strain reported in 2015; obligate heterofermenter (OHL)

- Utilizes hexose sugars with co-metabolism of ribose and galactose

- Appears to survive pasteurization and can grow under Cheddar cheese compositional and ripening conditions

Key Takeaways

Data from Cheddar cheese trials

In trials, Lb. wasatchensis was added to cheese milk with two levels of ribose and galactose added to curds at salting. The cheese ripened at 6 or 12 °C with interesting findings;

- At 12 °C during ripening there was faster decrease in starter lactococcal viability in presence of Lb. wasatchensis which caused more rapid growth and higher NSLAB populations also. Remember the higher NSLAB populations the more uncertain the quality outcomes are.

- The gas formation was higher in cheeses with Lb. wasatchensis added at both 6 °C and 12 °C and was higher at 12°C.

- Highest gas produced in cheese when both ribose and galactose added

Lb. wasatchensis will benefit on autolysed lactococci, since it can feed from ribose as a sugar source

Lb. wasatchensis, also reduced lactococcal counts during ripening

So, a likely interaction with starter bacteria occurs but the mechanism is currently unknown.

Lb. wasatchensis was also present in control cheeses but not detected until ~16 weeks reaching 105-107 CFU/g. This is very important, if you test your milk or fresh curd for Lb. wasatchensis you most probably won’t find it. Might still be there and cause problems later on.

Lb. wasatchensis is present in cheese as a slow growing NSLAB strain and when present in high numbers is associated with late gas production, specially with increased ripening temperature

Adjunct NSLAB

Population dynamics differ from typical NSLAB.

Figure 3a.7. Addition of adjunct NSLAB and viability during cheese ripening (Hou et al., 2017). a and b. SLAB Lactococus population growth during ripening. c and d. Adjunct St thermophilus population during ripening. e and f. Non-starter lactic acid bacteria (NSLAB) during ripening: in low drain pH, LDpH (broken line, open symbol) and high drain pH, HDpH (solid line, closed symbol) Cheddar cheeses made with control starter culture (LDpHC, ![]() ; HDpHC

; HDpHC ![]() ), control starter culture with a galactose metabolizing S. thermophilus culture adjunct LDpHGal+,

), control starter culture with a galactose metabolizing S. thermophilus culture adjunct LDpHGal+, ![]() ; HDpHGal+,

; HDpHGal+, ![]() ) or control starter culture with galactose non-metabolizing S. thermophilus culture adjunct (LDpHGal−,

) or control starter culture with galactose non-metabolizing S. thermophilus culture adjunct (LDpHGal−, ![]() ; HDpHGal−,

; HDpHGal−, ![]() ). Presented values are the means of three replicate trials; error bars represent standard deviations of the mean.

). Presented values are the means of three replicate trials; error bars represent standard deviations of the mean.

NSLAB: Commercial adjuncts

- A range of NSLAB based flavour enhancing adjuncts are available to accelerate ripening, debitter cheese and provide particular sensory notes or profiles

- Many are single strains of NSLAB e.g Lb. plantarum or Lb. casei chosen for flavouring properties such as high aminopeptidase activity and highly autolytic properties

- Added directly to cheese vat (DVI) as dried preparations

Key Takeaways

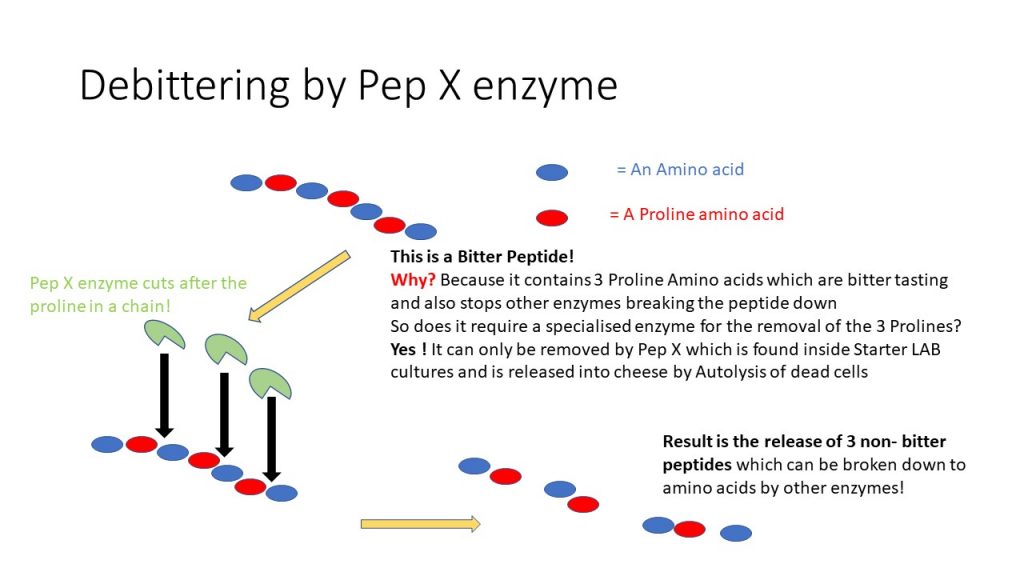

Debitter cheese; How is that?

Bitterness is a common problem found associated with accelerated cheese ripening process and other cheese manufacturing issues (low salt cheese for example). The culprit are peptides containing hydrophobic amino acid residue. Chymosin is important in the production of bitter peptides, since residual coagulant in Cheddar releases extremely hydrophobic peptides from β-casein. Cutting the coagulum at a low pH in Cheddar manufacture results in the retention of excessive chymosin and the development of bitterness. A low salt content in the final cheese will enhance chymosin activity and result in the accumulation of bitter peptides.

An attenuation treatment for debittering NSLAB may be effective because lactobacilli with high enzyme activities die-off rapidly and lyse to release their retained high activity intracellular enzymes into the cheese matrix during early ripening. Apparently an enzyme system in the adjuncts effectively prevents or degrades bitter flavour compounds to non-bitter compounds.

Debittering by PepX

NSLAB Commercial attenuated adjuncts

NSLAB and other lactobacilli can be added to cheese milk in the form of adjunct attenuated cultures. Attenuation is a method of subjecting cells to heat/freeze shock, sonication, spray drying in order to:

- Inactivate acid production in the vat and/or,

- Enhance autolysis of cells to enable early release of intracellular enzymes into the cheese matrix

Attenuation mainly results in the enhancement of secondary proteolysis, i.e production of small peptides and free amino acids. Many attenuated adjuncts selected for high aminopeptidase and high PepX activities, which are enzymes able to break down the bitter hydrophobic peptides. This results in debittering. Freeze shocked attenuation appears to give best quality outcomes

Summary: NSLAB and Cheese

Advantages:

- NSLAB flora generally considered integral part of cheese ripening agents

- Allow more flavour diversity to occur in varieties

- Can enhance proteolysis and/or lipolysis in cheese

- Adjuncts and attenuated cultures shown to improve or accelerate flavour in varieties including reduced or low fat cheese

Disadvantages:

- Variety can mean a variation in quality and this is unpredictable.

- High NSLAB growth can result in crystal, gas or slit formation

Adjunct NSLAB and Cheese quality

Some examples:

- Lb. curvatus and Lb. paracasei improved proteolysis and lipolysis added as adjuncts in Caciotta cheese (Italy)

- Proteolysis and flavour development in semi-hard reduced fat cheese improved by addition of adjunct Lb. paracasei which increased aromatic flavours produced from branched chain Amino Acids (BcAA) in Samsoe cheese (Denmark)

- Improvement in Cheddar cheese flavour on addition of adjuncts; Lb. plantarum and Lb. casei better than Lb. curvatus with enhanced FAA formation (Ireland)

- Use of respirative NSLAB adjuncts (grown under shake flask aerobic conditions with heme added) of Lb. casei reportedly increased diacetyl and other aroma compounds of Cheddar cheese

References:

Crow, V., Curry, B., & Hayes, M. (2001). The ecology of non-starter lactic acid bacteria (NSLAB) and their use as adjuncts in New Zealand Cheddar, International Dairy Journal, 11(4–7), 275-283, https://doi.org/10.1016/S0958-6946(01)00057-7.

Hou, J., Hannon, J.A., McSweeney, P.L.H., Beresford, T.P., & Guinee, T.P. (2017). Effect of galactose metabolising and non-metabolising strains of Streptococcus thermophilus as a starter culture adjunct on the properties of Cheddar cheese made with low or high pH at whey drainage, International Dairy Journal, 65, 44-55, https://doi.org/10.1016/j.idairyj.2016.10.003.

Rehman, S., Banks, J.M., McSweeney, P.L.H., & Fox, P.F. (2000). Effect of ripening temperature on the growth and significance of non-starter lactic acid bacteria in Cheddar cheese made from raw or pasteurised milk, International Dairy Journal, 10(1–2), 45-53, https://doi.org/10.1016/S0958-6946(00)00022-4.

Rynne, N.M., Beresford, T.P., Kelly, A.L., & Guinee, T.P. (2007). Effect of milk pasteurisation temperature on age-related changes in lactose metabolism, pH and the growth of non-starter lactic acid bacteria in half-fat Cheddar cheese. Food Chemistry, 100(1), 375-382, https://doi.org/10.1016/j.foodchem.2005.09.062.

Settanni, L. & Moschetti, G. (2010). Non-starter lactic acid bacteria used to improve cheese quality and provide health benefits, Food Microbiology, 27(6), 691-697, https://doi.org/10.1016/j.fm.2010.05.023.

mesophiles are microorganisms which grow optimally in moderate temperatures, generally within the range of 20 to 45 °C

Colony Forming Unit per gram

clean in place

Direct vat inoculation or direct vat set cultures are freeze-dried starter cultures that can be directly added to milk