Unit 5.a. Cheese Safety

Cheese Safety and Risk Analysis

What is a Risk Analysis?

According to the World Health Association, risk assessment, risk communication and risk management are overlapping subcategories of risk analysis. In other words, risk analysis is everything we do to prevent potential hazards from causing harm.

But what is a food hazard?

A biological, chemical or physical agent in food or a condition of food with the potential to cause an adverse health effect.

How do we analyze risk?

By understanding its individual components.

Mathematically, risk is the product of the probability of an adverse event (P) and the severity of the adverse event (S)

That is;

R=P x S

What is that adverse event?

An adverse event is what happens when we fail to control food hazards. For examples: a baby chokes on a piece of jewelry that accidentally fell into a yogurt cup; an immunosuppressed man dies after eating fresh cheese contaminated with Listeria monocytogenes; or a child suffers anaphylactic shock caused by traces of peanuts in chocolate ice cream. So we need to start by understanding potential hazards in dairy. As the examples above suggest, food hazards can be of three types: Biological, Chemical and Physical.

Biological hazards

Biological hazards are pathogenic microorganisms, that is microbes able to cause illness in humans.

Sources of Biological Hazards in the Cheese plant

- Milk and other ingredients, especially raw milk

- Dirty equipment

- Recontamination during processing and packaging

- Hygiene practices

- Pests

- Cross-contamination, mainly, contamination of cheese from surfaces contaminated with raw milk

- Processing environment

Are pathogens really coming from so many sources?

The following table shows the sources of a pathogenic microorganism Listeria monocytogenes in US Hispanic cheese found in several studies.

Incidence of Listeria monocytogenes in U.S. Hispanic Style Cheese plants

| Milk | 0% (0/47) 0% (0/16) |

Moreno-Enriquez et al., 2007 Rosas-Barbosa et al., 2014 |

| Curds | 10% (3/30) | Rosas-Barbosa et al., 2014 |

| Equipment | 19.3% (33/171) | Rosas-Barbosa et al., 2014 |

| Food contact | 1.7% (2/119) 33.3% (10/30) 29.2% (14/48) |

Kabuki et al., 2004 Moreno-Enriquez et al., 2007 Rosas-Barbosa et al., 2014 |

| Floors | 25.7% (19/74) 6.3% (1/16) |

Kabuki et al., 2004 Rosas-Barbosa et al., 2014 |

| Cheeses | 6.3% (7/111) 3.4% (5/149) 17.5% (11/63) |

Kabuki et al., 2004 Moreno-Enriquez et al., 2007 Rosas-Barbosa et al., 2014 |

| Others | 11.3% (6/53) 0% (0/29) 31.3% (10/32) |

Kabuki et al., 2004 Moreno-Enriquez et al., 2007 Rosas-Barbosa et al., 2014 |

None of the sources of this bacteria was the milk used, but many of the cases were related to presence of the microorganism in equipment, floors and food contact equipment or tools. This table also suggests a high frequency for occurrence of Listeria monocytogenes (LM) in Latin American style cheese such as Panela. That’s because Panela, a rennet coagulated fresh cheese, is made with little or no culture. In the absence of acid development and competitive growth of LAB, organisms such LM are more likely to grow.

Incremental biological risk

Biological hazards are the most important hazards in any dairy plant not only because raw milk can be a source of multiple pathogens but also because milk and many dairy products are perfect media for many pathogens to grow.

Why is milk such a good media for microbial growth?

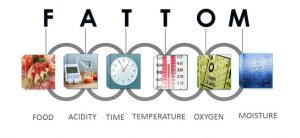

To understand this, lets use an acronym used by food safety professionals to describe the factors that control microbial growth:

F, Food: As we mentioned milk can be a source of several pathogenic microorganisms.

A, Acidity: Milk pH is close to neutral, which is perfect for many microorganisms.

T, Time: The longer the storage of milk or its processing the more time there is for microorganism to grow. On the other side, ripening of certain cheeses, especially those with lower water activity can reduce the number of pathogenic microorganisms.

T, Temperature: each microorganism has an optimum temperature to grow and a range of temperatures where it can grow. Milk is processed in a wide range of temperatures.

O, Oxygen: Milk and dairy products can offer different aerobic or anaerobic conditions for microorganisms to grow.

M, Moisture (and water activity): Milk is a very high water activity food. Microorganisms need water to survive. In cheese making, one of the purposes of the process is to reduce the water activity of milk.

How some factors affect bacteria?

Growth of pathogenic bacteria in foods: survival

| pH | Aw | Temperature | Salt as % of moisture | |

|---|---|---|---|---|

| Many pathogens grow | 5.6 - 7.0 | 0.9 - 1.0 | 10 - 40 ºC | <10% |

| Few pathogens grow, many survive | 4.4 - 5.6 | 0.85 - 0.9 | <10, 40 - 55 ºC | 10 - 20% |

| Few pathogens grow, some survive | <4.4 | <0.85 | >55 ºC | >20% |

Various sources. Salt in moisture data is adapted from IDF Fact Sheet 001 2017, The Importance of salt in the manufacturing and ripening of cheese.

Where do you see Parmesan Cheese being in the table?

Complicated or not? The individual properties of cheese are complex and do not necessarily fit into one single category, for example Aw in Parmesan Cheese:

Now in terms of other attributes, Click on the right ranges for each attribute in Parmesan Cheese:

So it might look like a few pathogens might survive and grow in Parmesan, but hurdles do not act independently; they act together creating a response bigger than their parts, so that the sum of all these hurdles is that pathogens are unlikely to grow in Parmesan Cheese.

Chemical hazards

Chemical hazards found in cheese products can either enter through milk ingredients or through cross-contamination like

• Allergens, remember that peanut butter sandwich you brought to the lunch room?

• Drug residues, that can be of harm to humans but can be specially harmful for the cheese making process.

• Mycotoxins (from ingredients or created during ripening)

• Pesticides

• Cleaning chemicals & sanitizers

Remember there are 11 recognized allergens in Canada and 8 in the US.

Allergen Types of mandatory label declaration in Canada and USA

| USA | CANADA |

|---|---|

| Eggs | Eggs |

| Milk | Milk |

| Fish | Mustard |

| Shellfish | Peanuts |

| Tree Nuts | Crustaceans and Molluscs |

| Peanuts | Fish |

| Wheat | Sesame Seeds |

| Soy | Soy |

| Sulphites | |

| Tree Nuts | |

| Wheat |

Drug residues, especially presence of antibiotics in milk, are important in cheese making since they inhibit the growth of starter and secondary cultures. Therefore, all milk must be tested before processing, i.e. tankers are tested before unloading. In Canada, there are strict controls for antibiotic residues in milk. For more information, go to http://www.omafra.gov.on.ca/english/livestock/goat/news/dgg1408a6.htm

Chemicals and sanitizers are also very important in cheese making and in the processing of fermented milks since some chemicals can inhibit starter cultures and/or rennet and other coagulants.

Source and Types of Physical hazards

- Glass – bottles, jars, light fixtures, gauge covers

- Metal – shavings, equipment parts, cheese molds, wires from cheese harps, screens

- Plastic – packaging material, pallets, equipment covers, cheese molds

- Wood – pallets, boxes, building structure, aging boards

Physical hazards can be harmful to humans, e.g., a piece of glass inside cheese could cut somebody’s throat. But most frequently, physical hazards can harm cheese making businesses by causing a recall, decreasing consumer trust and therefore impacting sales.

Now that we understand what the main hazards in cheese making are, lets go back to the concept of risk:

Risk

R=P x S

Risk equals probability of occurrence (P) multiplied by the severity of the adverse event (S)

Properties of pathogens associated with cheese

| Organism | Properties |

|---|---|

| Listeria monocytogenes | • Infectious, relatively high doses • Cold, acid and salt tolerant • Requires full pasteurization • Ubiquitous in food environments • Fatality rate 30-50% in newborns. High fatality rate in the elderly. Serious complications. |

| Campylobacter jejuni | • Infectious, low doses • Can cause Guillan Barre Syndrome |

| Salmonella spp. | • Infectious, low doses • Might end in septicemia or other important complications |

| Enteropathogenic E. Coli (e.g., 0157 H7) | • Infectious, low doses • Cold and acid tolerant • In cheese usually from milk • 8% evolves to Hemolytic Uraemic Syndrome |

| Yersina enterocolitica | • Psychrotrophic • Can cause septicemia and other serious complications |

| Staphylococcus aureus | • Usually from people contact • Rare fatality rate but some might cause MRSA |

Cheese borne hazards: prevalence in raw milk

| Food Borne Pathogen | Number of Studies | Prevalence: average % | Prevalence: range |

|---|---|---|---|

| Campylobacter jejuni | 9 | 3.1 | 0 - 12.3 |

| Shiga-toxin E. coli | 8 | 2.6 | 0 - 3.8 |

| Listeria monocytogenes | 16 | 3.8 | 1.0 - 12.6 |

| Salmonella spp. | 12 | 3.2 | 0 - 8.9 |

| Staphylococcus aureus | 1 | 34.6 | |

| Yersinia enterocolitica | 2 | 8.2 | 1.2 - 15.1 |

| Mycobacterium paratuberculosis | 1 | 68% (U.S. Study) | |

| Coxiella burnetii | 1 (Kim et al) | >94% (U.S. Study) |

So, according to this chart Coxiella burnetii and Mycobacterium paratuberculosis are the most prevalent pathogens in raw milk. However, these microorganisms are not the a common cause of recalls in Cheese.

Cheese Recalls in Canada due to microbial (2016 – 2020)

| Year | Total | Reason for Recall | |||

|---|---|---|---|---|---|

| Listeria | Salmonella | E. coli | S. aureus | ||

| 2020 | 11 | 4 | 1 | 3 | 1 |

| 2019 | 13 | 4 | 1 | 4 | 0 |

| 2018 | 12 | 0 | 1 | 5 | 2 |

| 2017 | 12 | 5 | 0 | 4 | 0 |

| 2016 | 11 | 1 | 1 | 3 | 3 |

Why is that? Why are the most common pathogens in milk not the ones causing recalls?

Once of the main reasons is the fact that cheese making is a process where a series of processing steps are used to change a high moisture product in solid product containing less moisture and different physico-chemical characteristics that prevent the presence and growth of microorganisms. In food safety, these steps are known as hurdles. and we have mentioned them in the “Growth of pathogenic bacteria in foods: survival” table above. These hurdles affect each microorganisms in different ways. Perhaps, the most important hurdle in cheese making is pasteurization.

Milk Safety

Milk leaves an animal at body temperature. For commercial milking species, body temperatures range from 100-104°F (38-40°C) depending on the species. Milk is virtually free of bacteria when secreted, if the animal is healthy and in good condition. Bacteria that contaminate the milk during its collection will grow at rapid rates – even doubling their population every 15-30 minutes if conditions are favourable. Optimum growth conditions for different bacterial species vary with respect to temperature, water activity, food source, pH, and available oxygen. We discusses this in Unit 2a slide 19.

Pathogenic and spoilage organisms are commonly (not exclusively) of the Mesophilic type, growing best at moderate temperatures. Mesophilic cultures grow at temperatures between 10-45°C with optimal growth between 30-37°C. Cooling the milk rapidly slows growth for these microorganisms. However, at temperatures between 21-28°C, psychrotrophic (psychro means cold) bacteria will multiply at a much faster rate. If milk is not properly cooled to at least 10°C in a very short period, psychrotrophic bacteria will take over the natural flora of the milk. This will create issues in the milk supply as the psychrotrophic bacteria produce lipolytic and proteolytic enzymes that will cause deterioration of the milk. Some of these enzymes can resist pasteurization and create serious quality problems in cheese including defects in texture, aroma and flavour.

Milk safety starts in the farm, continues during collection, transportation and delivery, and becomes a priority to cheese makers as soon as it gets into the plant. Milk receiving tanks should be separated from the rest of the spaces in the plant so that raw milk has very little chance to contaminate the milk or cheese after milk has been pasteurized.

Pasteurization

First, cheese makers can control microbial risks with legal pasteurization of reasonably high-quality milk as discussed in unit 2b. Pasteurization has been shown to produce at least a five-log reduction (enough to make it safe) in microbial populations for all major pathogens of concern for cheese making.

A more thorough consideration of legal pasteurization provides insight into the standards that need to be met for cheese makers to be confident and to satisfy regulators. Requirements for legal pasteurization can be found in the National Dairy Code, 1997 – Part II, 56-60. Proper equipment design and operation ensures that every drop of milk is pasteurized, sealed equipment prevents tampering, and digital and analog temperature records provide evidence that all conditions are met.

A wide variety of other treatments are being used to reduce microbiological risks in milk (See unit2b). Some of these involve heat treatment of milk that does not meet the standards of pasteurization but may significantly reduce populations of pathogens. They also include bactofugation, clarification, and microfiltration. Other developing technologies use light, sound, pressure, competing or protective bacteria, filtration, ozone, or irradiation to kill or limit growth of pathogens. None of these have been accepted as equivalent to pasteurization. However, cheese makers (with the help of microbiology experts) may be able to demonstrate that a combination of procedures incorporating some of these technologies will consistently reduce pathogen populations in cheese to levels equivalent to those found in cheese made from pasteurized milk.

Legal pasteurization inactivates phosphatase in milk. This test should confirm that the pasteurizer was working effectively. Milk samples for phosphatase testing should be kept cold and tested quickly because phosphatase can renature resulting in false positives. Due to renaturation and production of bacterial phosphatase during ripening, the phosphatase test is not a reliable indicator of pasteurization in cheese. This test is explained in Unit 2d.

To  pasteurize or not to pasteurize, that is the question….. (at least for cheese makers)We noted in the previous section that receiving clean milk is important for food safety. Cheese makers who choose not to pasteurize will benefit greatly from milk with low pathogen counts. Clean farm conditions, healthy animals and choices of feed enable farmers to provide milk with relatively low levels of microbiological risk. Sourcing of clean raw milk is an essential part of the food safety program for cheese makers, but only one of the many steps for food safety.

pasteurize or not to pasteurize, that is the question….. (at least for cheese makers)We noted in the previous section that receiving clean milk is important for food safety. Cheese makers who choose not to pasteurize will benefit greatly from milk with low pathogen counts. Clean farm conditions, healthy animals and choices of feed enable farmers to provide milk with relatively low levels of microbiological risk. Sourcing of clean raw milk is an essential part of the food safety program for cheese makers, but only one of the many steps for food safety.

Cheese makers that use raw milk face the challenge of knowing and documenting that every batch of milk meets strict quality standards. This may require expensive testing for several common pathogens. Since testing of raw milk will likely not eliminate pathogens to a level equivalent to pasteurization, this will only be one step in a series of choices to reduce risk. Collectively, this series of choices is referred to as the “hurdles” used to reduce risk. These hurdles apply for cheese made of both raw and pasteurized milk, but become more important for raw milk cheese.

Other Pathogenic Hurdles in Cheese Making

If I were asked to create a new meaning of the term cheese making I would write something like this: ““Cheese making is a technical and artistic act of putting microbial hurdles into milk to create safe delicious products. In fact, many steps in cheese making can be considered as hurdles that contribute to cheese safety.” The following table enumerates the most important hurdles used to decrease risk during the transformation of milk into cheese.

| Hurdle | Effects |

|---|---|

| Standardize microflora | Microfiltration, pasteurization, bactofugation |

| Cultures | Time versus pH profile, antimicrobials, surface ripening, |

| Water Activity (Aw) | Aw , salt in moisture |

| Temperature History | E.g., Pathogenic survival dramatically reduced in thermophilic cheeses |

| Exposure History | E.g., Parmesan versus Cheddar; especially critical for fresh including heat-acid cheeses. |

| Ripening Time | Pathogens decline due to low pH, decreasing aw , antimicrobials, and low oxygen |

| Cold storage of milk | Slows or stops growth of both pathogens and competitors |

How much can these hurdles affect cheese safety?

| Pathogens behaviour | pH | aw | |||

|---|---|---|---|---|---|

| Most pathogens grow at: | 5.6 7.0 This is the pH of milk and the pH of curd during most part of cheese manufacture |

0.9 1.0 Most cheese fall under this Aw range. |

|||

| For a overlook of pH behaviour during processing visit the ebook | For a overlook of the Aw of certain cheese visit the ebook | ||||

| Few pathogens grow but many survive at: | 4.4 - 5.6 Most cheese fall on this range. |

0.85- 0.90 Very few cheeses might go as low in water activity. Parmigiano Reggiano might be one, but even Romano cheese has Aw higher than 0.91 |

|||

| Few pathogens grow. Some survive at: | <4.4 Almost none of the cheese fall in this range |

<0.85 Almost none of the cheese fall in this range |

|||

| Temperature history °C | <10 Very slow grow |

10-45 Psychrotrophs and mesophilic growth |

45-55 Thermophilic growth |

>55 No growth |

|

| Temperature storage | <4 slows or stop pathogen growth |

34-37 optimum for many pathogens |

>55 Most pathogens will NOT grow |

||

| Cultures | microbial competition | produce inhibitors | increase acidity | ||

| Salt in moisture % | <1 No effect |

1-3.5 Very Little inhibition |

>3.5 Major inhibitory effects but Listeria tolerates 15% salt! |

We must highlight the fact that hurdles do not act independently. That means that each of them contributes to food safety. For example, a cheese like Roquefort might present a high pH (e.g. 6.3). at this pH everything might grow. But the same cheese has a relatively low water activity (0.91) and a high salt concentration (9%). These two last hurdles are enough to render the cheese safe, despite its high pH. Hurdles act in a synergistic way, they do not add, they multiply.

This information might make cheese look like the most dangerous food in the planet, but in reality cheese manufactured in developed countries where general food safety principles are known, encouraged and/or enforced is not an usual cause of food recalls or illnesses. The risks are higher in certain varieties with higher moisture or higher pH or cheese manufactured with raw milk. The exception is thermophilic varieties that include a high cooking step (>50 C, 30 – 60 min) along with other long ripening and low water activity.