Unit 3b. Secondary Cultures in Cheese making

Yeasts and Moulds

Yeasts and moulds are encountered in cheese manufacture in two contexts:

As food spoilage agents

- Growth on surface of inadequately sealed vacuum packs

- Gas production

- Discolouration on surface, spots, bleaching

- Undesirable aroma and appearance

- Undesirable flavour generation

As beneficial secondary cultures

- Added to internally and surface ripened cheese types

Sources of yeast and moulds include; grass, silage, raw and pasteurised milk, air, personnel, brine tanks, cheese plant, wooden shelves in ripening room and contamination of starter culture (Figure 3b.1). They enter the cheese process as spores, which are encapsulated, multi-layered dehydrated cells, also called dormant spores

Spores are notoriously heat resistant and remain dormant until conditions are suitable for germination. If they germinate they grow into actively dividing vegetative cells and can revert to spores again.

Main requirement for germination besides nutrient is oxygen. That is why damaged packs or not properly vacuumed packs encourage growth on surface.

Most cheese varieties contain yeast and mould spores. The main food safety concern is possible growth of aflatoxin producing moulds, e.g Aspergillus flavus

Yeasts: Growth conditions

Yeasts can grow in a low pH environment (as low as 2.0-2.5) with growth range from 4.5-7.0. Growth temperature range is from 2 °C to 30 °C but many capable of growth over the range 2 °C to 10 °C. Yeast can also tolerate high salt and low water activity conditions with some species able to tolerate up to 24% salt. That is why brine is a major source of Yeasts. Brine can contain 103 to 109 CFU/ml mainly Debaryomyces sp.

Raw milk usually contains 103 CFU/ml of yeasts. Both Yeasts and Moulds have proteolytic and lipolytic enzymes and have a major impact on flavour and texture development

Yeasts and Moulds

A commercial cheese survey USA (2015) looked at 44 cheeses, 8 different varieties including Cheddar, Swiss, Parmesan-type, Dutch and soft cheeses tested and found that:

- Debaryomyces hansenii most prevalent yeast in all varieties. (~80% of all cheeses) followed by Geotrichum candidum (13% of all cheeses)

- Most prevalent moulds detected in all varieties were Penicillium sp. in 45% of cheeses and Aspergillus sp. in 11% of all cheeses

Yeast and Moulds in Cheese making

Yeasts and Moulds are used in a wide range of semi-hard and soft cheese types

- Internal mould ripened cheeses like Blue Cheese, Gorgonzola, Roquefort

- Surface ripened cheeses like Brie, Camembert, and as part of the smear ripened cheese process

Importance of Yeast and Moulds is derived from their carbohydrate metabolism and contribution of their proteolytic and lipolytic enzymes. Some proteinases and lipases are secreted extracellularly. There is a wide variation in proteinase and lipase activity within species and cultures are tailored for each cheese variety. For example, use of different subspecies of P. roqueforti to create different flavour profiles in blue cheese.

Danish Blue contains highly proteolytic and lipolytic Penicillum moulds.

Energy sources: Carbohydrate Metabolism

The normal pH levels after curd manufacture of soft cheese e.g Camembert is 4.8-5.0. During curd manufacture lactate is generated by lactococcal starter cultures, then yeasts on surface can utilise lactic acid as a carbon source and oxidise it to CO2 and H2O .

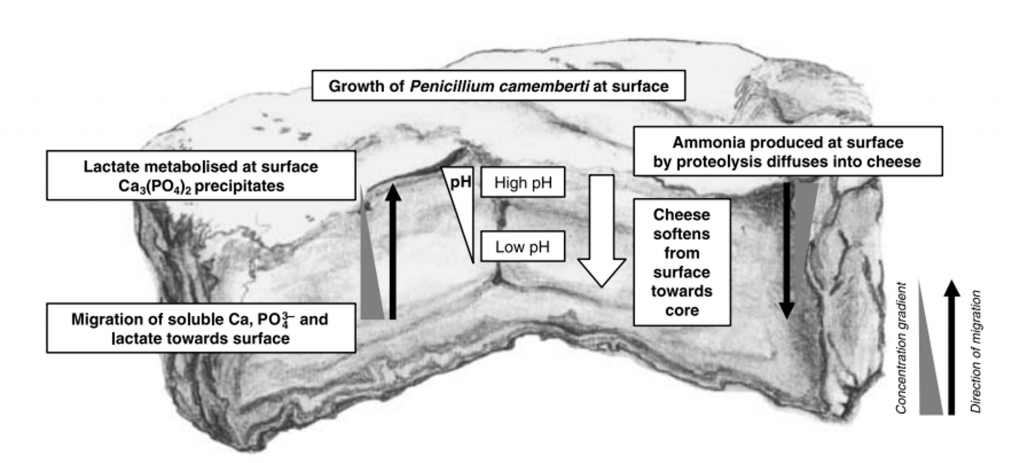

This use of lactic acid in cheese produces deacidification of cheese surface with an increase in pH. Since yeast develop on the cheese rind where plenty of oxygen is available, a gradient is formed with higher pH on surface (cheese rind) and lower internal pH (cheese core). Diffusion of lactate from core to surface of cheese, establish a gradient of pH, lactate and texture in the cheese.

The yeasts and moulds assists in softening the cheese texture and improves conditions for proteolysis and lipolysis (Figure 3b.3)

An undesired yeast, Kluyveromyces marxianus can use lactose in milk and can grow in cheese interior (anaerobic) causing off flavours and gas.

Commercial cheese Yeast and Moulds cultures

D. hansenii, K. marxianus and Geotrichum candidum are most commonly used in surface ripened cheese. Cheese makers can get specific commercial strains of each differing in proteolytic and lipolytic activities activities while both Geotrichum candidum and Penicillium camemberti secrete lipolytic enzymes.

Some of them form white fluffy colonies on cheese surface (G. candidum mainly), these colonies give this cheese the name of bloomy rinds.

To apply in cheese, cheeses are washed in brine and also yeasts sprayed onto the surface usually in a brine solution. Regular turning and re-spraying is done if necessary

However for surface ripened cheese, after the lactate content has been exhausted, amino acids are also used as a growth substrate by Yeasts and Moulds. During its utilization, amino acids are both decarboxylated and deaminated to generate ammonia (NH3) which cause a further increase in pH of the cheese.

At end of ripening surface pH is ~7.0 while internal pH is ~6.0

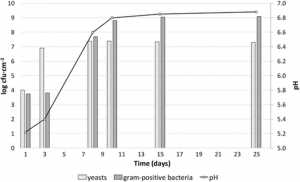

Figure 3b.2. Changes in pH in relation to microbial growth (Fröhlich-Wyder et al., 2019)

Yeasts: Surface Growth

Initially surface of cheese has low pH and high salt content. The initial colonisation is by acid and salt tolerant yeasts and moulds (e.g Penicillium camemberti). In particular, P. camemberti which is an aerobic mould species provides the main microflora on the surface of Camembert cheese. This mould grows in two stages on the cheese, the first stage is when it uses the residual lactose in the cheese and forms a dense mycelium coating on the cheese. After lactose has been used up it, in the second stage of growth it uses the lactic acid in the cheese along with peptides and amino acids and converts them to ammonium which increases the cheese pH, especially at the surface, causing a softening in texture. During this second stage of growth the P. camemberti generates spores which require germination to continue a new growth cycle.

Lactate converted to CO2 and H2O with pH increase from 5.0 up to 7.0 which also enables bacterial growth of 108-1010 CFU/cm2

For Camembert, Brie and other surface ripened cheeses yeast are the predominant microflora during ripening, but for smear ripened cheeses (washed rind cheeses) such as Oka, Munster, Tilsit, Taleggio the yeast are allowed to grow and raise the pH but are washed off and a red smear culture is applied. For these type of cheese, red smear culture Brevibacterium linens is the dominant flora thereafter. But the activity of yeast is pre-requisite for B. linens growth.

Figure 3b.3. Changes that occur due to the growth of Penicillium camemberti on the surface of Camembert-type cheese during ripening (McSweeney & Fox, 2004).

Yeasts and Smear ripened cheeses

- Debaryomyces hansenii often is the major component of the surface yeast microflora of smear ripened cheese. Yeasts can be sprayed onto the cheese or they can develop from the “house” flora and reach 108-109/g after ~7 days

- Yeasts also produce growth factors to stimulate bacteria, e.g panthotenic acid, nucleotides, peptides

- Change in pH due to yeast growth allows establishment of red smear through growth of bacterial species such as Brevibacterium, Arthrobacter, Micrococcus and Corynebacteria. These bacteria are moderately acid tolerant, are salt tolerant with a range of proteolytic and lipolytic activities for flavour development

- Increase in pH is more optimal for proteinases and lipases especially increase in pH is more optimal for proteinases and lipases especially for enzymes that can release proline which when found within a peptide can cause bitterness in cheese.

- Yeast are then replaced as dominant surface population by bacterial species above

Moulds and cheese ripening

Moulds such as Penicillium camemberti and Penicillium roqueforti and added as spores to milk in manufacture of cheeses such as Roquefort and Blue varieties, blue veined cheese. These cheeses are internally mould ripened and also have a surface mould growth.

To encourage growth during ripening cheeses are pierced to enable entry of oxygen and outgrowth of spores. Starter cultures in curd manufacture are usually gas producers which open the structure of the cheese and also the cheeses are only turned and not pressed thereafter.

If you want to explore more what cheesemakers do to manage blue mould growth, you can watch this video about how Stilton Cheese is made.

P. roqueforti has internal and secreted proteinases and peptidases and causes extensive proteolysis of both α-S1 and β-caseins; bitterness from β-casein hydrolysis can be a feature of “strong” flavoured Blue cheese.

P. roqueforti also produces extracellular lipases and esterases. Lipolysis by P. roqueforti generates acetic, butyric (C4), caprylic, and caproic acid (C6). These and other fatty acids (C2-C12) are then oxidised to produce methylketones (2-heptanone and 2-nonanone) which contribute to typical flavour and aroma of Blue type cheese. This process is known as β-oxidation pathway. Production of methylketones is greatly increased in presence of oxygen. High levels of lipolysis occurs in mould-ripened cheeses; 5–10% of total triacylglycerides are hydrolysed in Camembert and up 20% are hydrolysed in other blue-vein cheese. Levels of 18–25% of total fatty acids as FFA have been noted in Danish Blue cheese.

Branched chain fatty acids (e.g 3-methylbutanoic acid) also generated which give “sweaty” and “cheesy” aroma compounds.

Esters generated by joining of an alcohol and fatty acid are also catalysed by mould enzymes and are contributors to flavour.

Practical issues

If manufacturing a range of smear and mould ripened cheese within the same premises:

- Need to segregate ripening operations as spores are highly mobile (airborne) and resistant to cleaning, possibly contaminating areas beyond cheese hall

- Need to ensure personnel obey hygiene instructions and that workflow is such that cross contamination is avoided

- Blue mould appearance on smear ripened cheeses is highly undesirable.

- Brine tanks may need to be separated depending on varieties made

- Utensils such as piercing rods and cheese moulds need to be kept separate from smear operations and cleaned

- If making vacuum packed cheeses e.g Cheddar, need to ensure airtight condition of pack maintained

Reference:

Fröhlich-Wyder, M-T., Arias-Roth, E., & Jakob, E. (2019). Cheese yeasts. Yeast, 36, 129–141. https://doi.org/10.1002/yea.3368

McSweeney, P.L.H. & Fox, P.F. (2004). Metabolism of Residual Lactose and of Lactate and Citrate. In P. F. Fox, P.L.H. McSweeney, T.M. Cogan, & T.P. Guinee (Eds.), Cheese: Chemistry, Physics and Microbiology (Vol. 1, pp. 361-371), Academic Press.

https://doi.org/10.1016/S1874-558X(04)80074-5.

Colony forming units per milliliter

Enzymes that break proteins and peptides into smaller peptides and aminoacids

an enzyme that catalyzes the breakdown of fats in a process called lipolysis