Unit 5a. Lactic Cultures in Yogurt and Kefir

Yogourts and Fermented Milks

What is yogourt?

Yogourt is a dairy product produced from the bacterial fermentation of milk. The Food and Agriculture Organization of the United Nations/World Health Organization (FAO/WHO) define yogourt as: “the coagulated milk product obtained by lactic acid fermentation through the action of Lactobacillus delbrueckii ssp. bulgaricus (L. bulgaricus) and Streptococcus thermophilus (Strep. thermophilus) from milk and milk products. The microorganisms in the final product must be viable and abundant.” If other bacteria are added, such as probiotics (e.g., bifidobacteria, lactobacilli species.), the product must be called “fermented milk” and cannot carry the yogurt label.

Codex Alimentarius entry for fermented milk (Codex STAN 243-2003) specifies that yogurt should contain a minimum of 2.7% (m/m) milk proteins, a maximum of 15% milk fat, a minimum of 0.6% titratable acidity (expressed as % of lactic acid), and a minimum of 107 CFU/g of microorganisms (total microorganisms in the starter culture).

Definitons by the Canadian Dairy Code

22. Yogourt

- Description. Yogourt is the food obtained by lactic acid fermentation through the protosymbiotic mixture action of Streptococcus thermophilus and Lactobacillus delbruckii subsp. bulgaricus from milk ingredients and modified milk ingredients to which may have been added optional permitted ingredients listed below.

- At the time of sale for consumption, yogourt shall have viable, active and abundant micro-organisms, except in the case of heated treated yogourt.

- The acidity of yogourt shall be not lower than 0.70% per weight expressed as lactic acid from the activity of the micro-organisms. Minimum counts of characteristic micro-organisms shall be 107 CFU/g at the time of sale.

- Yogourt shall contain at least 9.5% milk solids non fat or at least 7.6% milk solids non fat in the case of yogourt with added fruit.

- Yogourt drinks shall contain at least 6.5% milk solids non fat.

- Yogourt shall contain at least 2.8% milk proteins in the final product or 2.2% milk proteins in the case of drinkable yogourts (yogourt drinks).

- Optional Ingredients. Yogourt may contain the following safe and suitable ingredients: milk and milk ingredients, starter cultures of harmless microorganisms, fruits, juice or fruit extracts, jams, cereal, spices, vegetables, confections, seasonings, herbs, nuts or any other flavour, sweeteners, sweetening agents and permitted food additives.

- Nomenclature. The name of the food shall be yogourt (with alternative spellings), or yogourt drink or alternatively drinkable yogourt in the case of yogourts which are to be drunk. Yogourt which, after fermentation, has been pasteurized or sterilized, shall bear in legible and uniform print, the size of which is at least half the size of the largest print on the container, the name ‘pasteurized after fermentation’ or as the case may be, ‘sterilized after fermentation’, placed immediately after the name of the food. When the word ‘natural’ is used along with the name yogourt, neither artificial flavours, flavouring agents, preservatives nor artificial colours may be present in either the natural yogourt or ingredients of fruit or flavouring of the (naming the flavour) yogourt.

23. Buttermilk

- Description. Buttermilk is the liquid food obtained by the fermentation of milk and the addition of bacterial culture. The food shall contain not more than 3.25% milk fat, not less than 8.25% milk solids non fat and not less than a titratable acidity of 0.7%.

- Optional Ingredients. Buttermilk may contain the following safe and suitable ingredients: starter cultures of harmless microorganisms, milk ingredients and modified milk ingredients, salt and permitted food additives.

- Nomenclature. The name of the food shall be buttermilk.

24. Sour Cream and Cultured Cream

- Description. Sour cream is the food obtained by the fermentation of cream and/or milk ingredients and/or modified milk ingredients by the addition of coagulating agents and must contain a minimum of 14% milk fat and not less than a titratable acidity of 0.2%.

- Optional Ingredients. Sour cream may contain the following safe and suitable ingredients: milk ingredients and modified milk ingredients, buttermilk, starch, salt, flavours, rennet, microbial enzymes, enzymes and permitted food additives.

- Nomenclature. The name of the food shall be sour cream or alternatively cultured cream.

(National Dairy Code, 1997)

Basic raw materials

Cheeses and yogourts are made from similar basic raw materials, with a few differences. Try out this activity to test your knowledge on basic raw materials used to produce cheese and yogourt.

Yogourt Variants

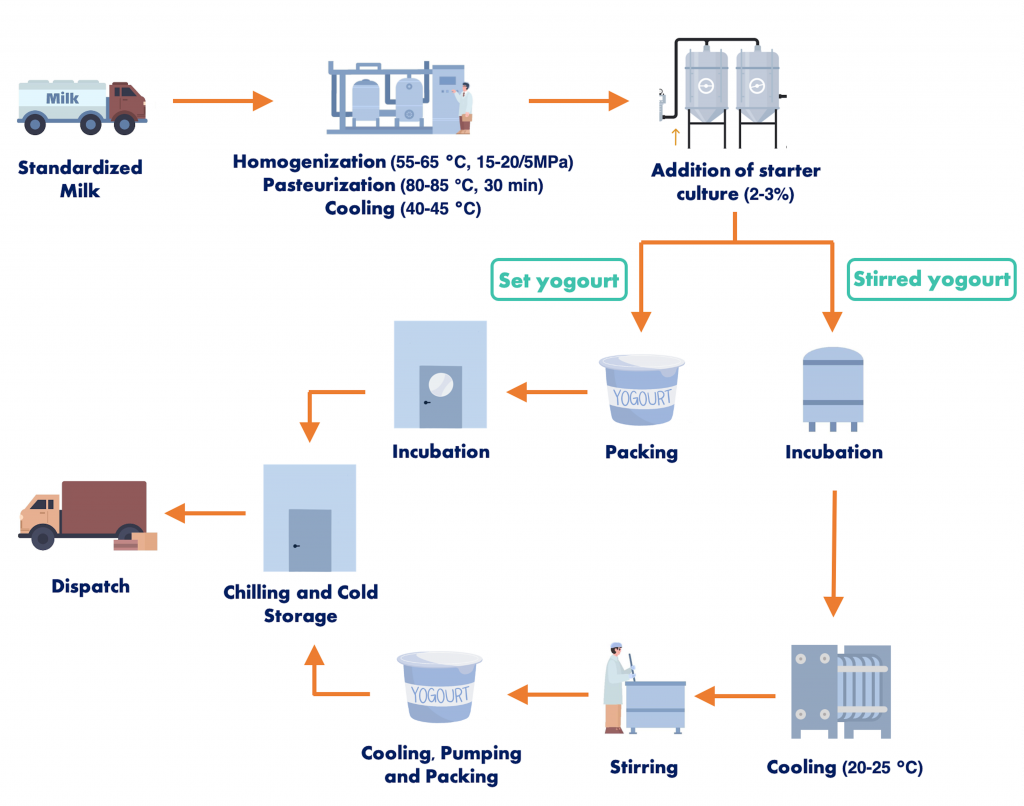

Stirred yogourts are the most common types of yogourts and are fermented in tanks, cooled with the curd broken up, fruit added and then packed.

Set yogourts are yogourts which undergo fermentation without stirring and are fermented in the pack (including any fruit or rennet addition), cooled and then sealed.

Greek Yogourts are manufactured either from milks fortified up to 9-10% protein or from curds concentrated by centrifugation or ultrafiltration (similar to cream cheese). Traditionally curds were strained to remove whey, lactose and minerals giving a rich, thick, high protein texture. To increase solids content, ultrafiltration is now mostly used as it retains more protein than centrifugation.

Greek style yogourt now accounts for ~50% of the North American yogourt market. The by-product of making Greek yogourt is acid whey, which has very limited applications and can be difficult to process further or to discharge as waste.

Yogourt Production

Figure 5a.1. Yogourt Production (Adapted from Kaur et al. 2017)

Milk homogenization and pasteurization

Milk is the principal ingredient used in making yogourt. The milk used for yogourt production typically undergoes homogenization and pasteurization.

When raw milk is left undisturbed, milk fat can rise to the surface and form a cream layer. Homogenization prevents the separation of cream and skim. This treatment can enhance the colour of milk, resulting in a “whiter” colour, and can increase yield by minimizing the loss of milk fat during processing. Homogenized milk is not normally used for cheeses.

However, homogenization of milk can also lead to unfavourable outcomes. Homogenization can make milk fat particles more susceptible to lipase attack, which can lead to the formation of free fatty acids that contribute to the production of rancid flavours. Homogenized milk may also be more prone to oxidation.

The European Union Directive 92/46/EC stipulates that pasteurization of milk must be carried out normally at HTST (72 οC for 15 s) or UHT (135 οC for 2-5 s) conditions. Yogourt is typically pasteurized at 90 οC for 1-2 min, or 85 οC for 30 min. Pasteurization is a critical control point (CCP) in a milk processing plant and can inactivate enzymes in milk, including lipase. An alkaline phosphatase test can be used as an indicator of proper pasteurization of milk and milk products.

A plate heat exchanger is used to carry out milk pasteurization. It consists of a: heating section, holding section, regeneration section and cooling section.

Heating also affects the milk structure. Heat treatment can give a firmer consistency and incorporates whey proteins into the gel, which results in less wheying off from the gel. Thus, pasteurization is not only considered a safety procedure, but also a heat treatment aimed at imparting specific properties.

Table 5a. 1. Milk pasteurization conditions

| Product | Pasteurization Type | Time | Temperature |

|---|---|---|---|

| Milk Based Products - below 10% MF | Batch/Vat | 30 minutes | 63 °C 145°F |

| Milk Based Products - below 10% MF | HTST | 15 seconds | 72 °C 161 °F |

| Milk Based Products - 10% MF or higher, or added sugar (fluid cream, chocolate milk, flavoured milk) | Batch/Vat | 30 minutes | 66 °C 151 °F |

| Milk Based Products - 10% MF or higher, or added sugar (fluid cream, chocolate milk, flavoured milk) | HTST | 15 seconds | 75 °C 167 °F |

Cooling and inoculation

After pasteurization, milk needs to be cooled to ~45 °C and then inoculated with starter cultures to initiate fermentation.

Starter Cultures

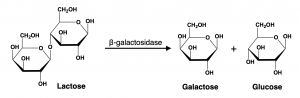

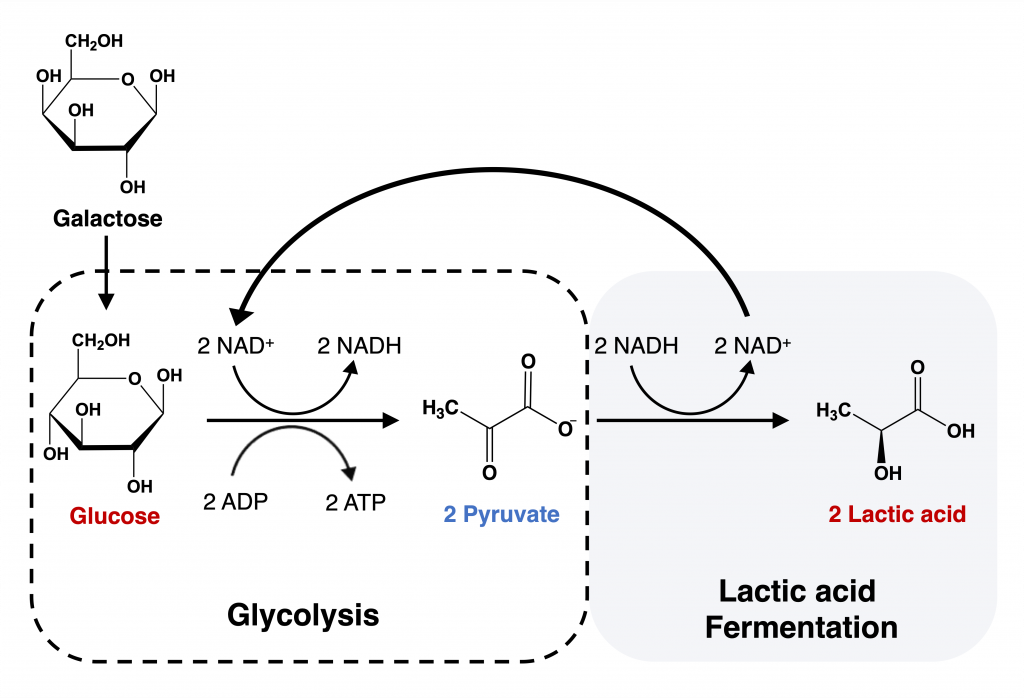

Starter cultures are used to carry out milk fermentation during cheese and yogourt making. This process converts lactose into lactic acid (Figure 5a.2. and Figure 5a.3.).

Figure 5a.2. Lactose Breakdown

Figure 5a.3. Lactic acid fermentation

The accumulation of lactic acid reduces the pH of milk. In cheese making, the pH is usually reduced to 5.2 from 6.6, which is not low enough to induce coagulation. For some cheeses, however, some starter cultures can be used to decrease the pH to 4.6 where coagulation can occur. In yogourt making, the pH is typically reduced to 3.8 to 4.4 to induce coagulation and give yogourt its characteristic texture.

One of the functions of starter cultures is to colonise the product with beneficial bacteria and out compete pathogenic bacteria. Starter cultures also provide a source of lactase (β-galactosidase) for lactose intolerant consumers.

Starter cultures can also:

- Prolong shelf life

- Produce desirable end products

- Flavours from proteins and fats

- Aroma compounds e.g. acetaldehyde

- Texture from “ropy” strains or exopolysaccharide (EPS) producers

- And some can act as probiotics

Yogourt Starter Cultures

Cultures can be obtained from commercial or bulk starter production.

Thermophilic or “heat-loving” cultures grow optimally at 40 – 50 °C and are commonly used in yogourt production. Examples include:

- Lactobacillus delbruckeii subsp. helveticus (LH)

- Lactobacillus delbrueckii subsp. bulgaricus (LB)

- Streptococcus thermophilus (ST)

LB and ST strains are considered main yogourt starter organisms and must be present in the culture.

Other microorganisms may also be used, such as:

- Probiotics e.g. Lactobacillus acidophilus, Bifidobacterium spp. (“BA yogourts”)

- EPS producers (“thickener strains”)

Growth during Yogourt Production

Lactose in milk is the main growth substrate for LAB. D-Lactate is produced by LB and ST (from Glucose) up to ~1.8%, but Galactose in milk is not used by either ST or LB culture. Nitrogen is also required and is generated by proteolytic systems of the starters.

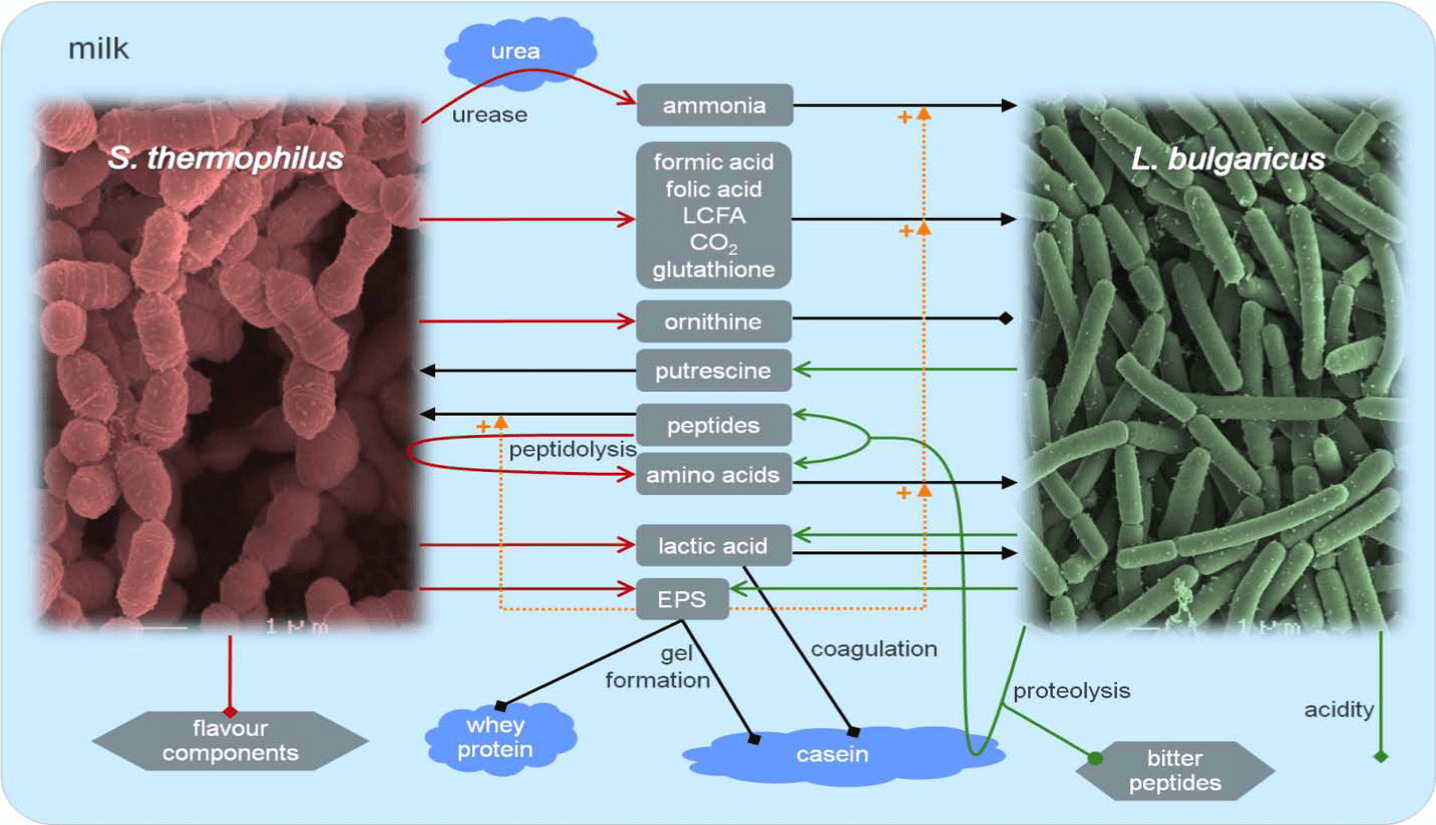

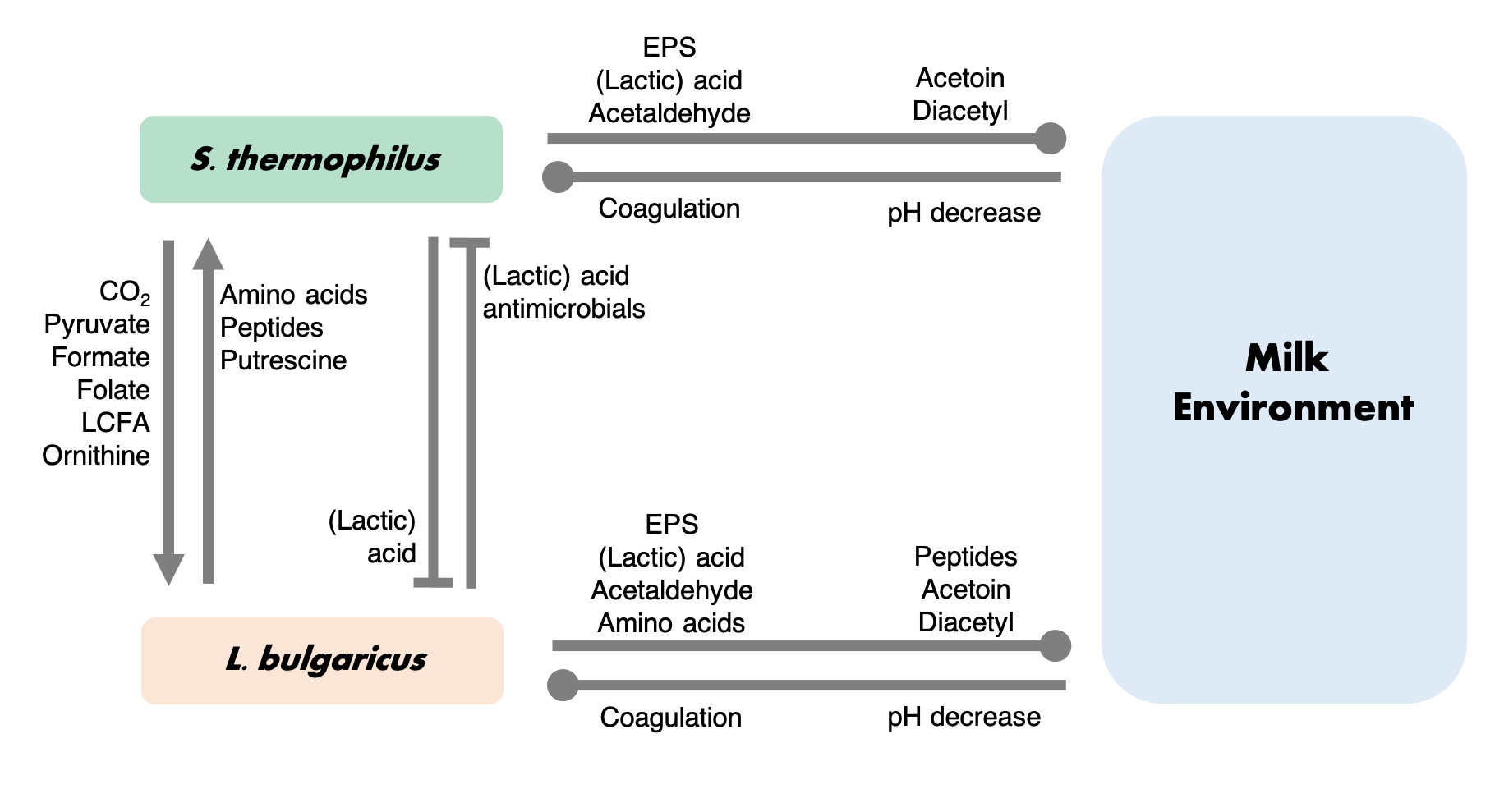

Figure 5.a.4. Interactions between St. thermophilus and Lb. bulgaricus

In short, after Lb. bulgaricus grows it generates a range of peptides, free amino acids and putrescine that stimulate the growth of S. thermophilus. S. thermophilus produces pyruvic acid, formic acid, folic acid, ornithine, long-chain fatty acids and CO2 which stimulate the growth of Lb. delbrueckii subsp.bulgaricus. S. thermophilus also reduces the pH of milk by generating lactic acid which stimulates growth of Lb. bulgaricus to an optimum level for Lb. delbrueckii subsp. bulgaricus. This relationship within LB and St is known as proto-cooperation .

Figure 5.a.5. explain in detail proto-cooperation in milk over time; at the start of the fermentation of milk with ST and LB, ST starts growing rapidly producing acids and CO2, but at some point it start lacking enough aminoacids required for its metabolism so growth slows down. During this transition period LB starts to grow and produce PrtB in abundance, which provides enough aminoacids for both ST and LB, so their growth speeds up.

During the second exponential, ST urease activity urea to ammonia and C02 and is essential for correct acidification by ST. Urease activity also stimulates Amino Acid metabolism by ST as it upregulates sulfur and branched chain aminoacids genes in the culture. During the stationary phase the high acidity inhibits growth of both cultures.

Figure 5.a.5. Proto-cooperation between between ST and LB

Figure 5.a.6. Summarizes the changes in milk due to ST and LB growth and its proto-cooperation; flavour and aroma compounds are created, milk coagulates, and the cultures sub-products improve growth and so metabolism of each culture.

Figure 5.a.6. Changes in milk due to ST and LB and its interactions.

Flavour production in yogourt

- Acetaldehyde: generated from amino acid threonine and present at 1 – 25 mg/L (mostly by ST)

- Diacetyl: present at 0.2 – 3 mg /L (mostly by ST)

- Acetoin, and

- 2,3-pentanedione

ST is vital for correct flavour and acid development in yogurt. ST provides the CO2 and Formic acid that is needed for growth of LB. ST starts the acidification process and reduces the milk pH to levels that encourage growth of LB. The urease enzyme of ST (THE ONLY LAB SPECIES TO CONTAIN UREASE) also converts urea into ammonia and CO2 (CO2 needed for LB growth and stimulates its acidification) Both cultures generate lactic acid, but also volatile flavour compounds such as acetaldehyde, diacetyl acetoin, acetone, and 2-butanone which contribute to the typical aroma of yogurt. It is important to note that when ST and LB are cultured together they produce more of these volatile compounds than when cultured separately. Streptococcus thermophilus generates acetaldehyde in the range of 1.0 to 13.5 mg/kg, while Lb. bulgaricus generates between 1.4 and 77.5 mg/kg in milk

Exopolysaccharide (EPS) Production

Examples of fermented milk products with EPS producers

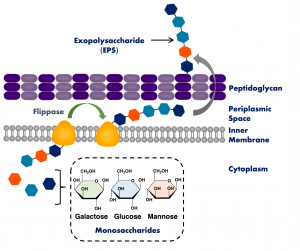

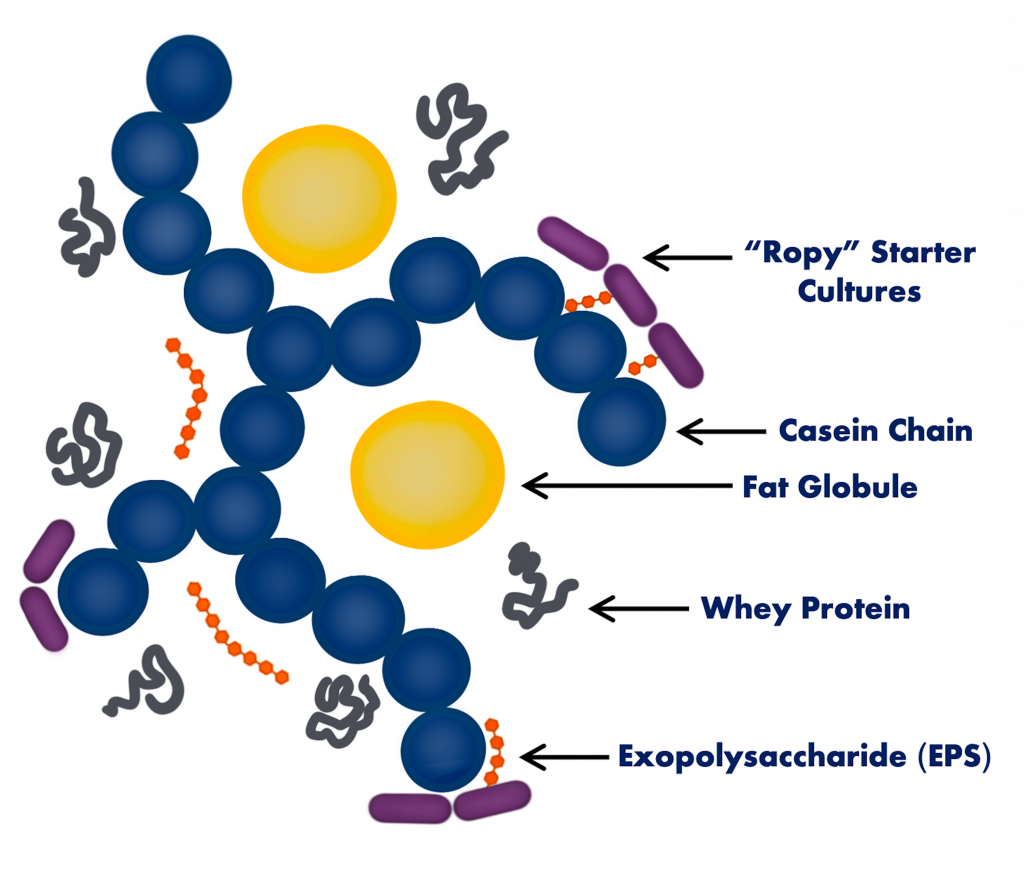

Exopolysaccharides (EPS) are produced by ST and LH and influence mouthfeel and texture of yogourt. EPS are sugar polymers composed of repeating units of simple sugar molecules (e.g. galactose), which are first generated within the cell interior and are then attached to a lipid carrier before being excreted into milk (Figure 5a.4).

EPS can bind to casein chains and also assist in retaining water in the gel, which may reduce whey expulsion or ”wheying off” (Figure 5a.5). ST generates EPS comprised of galactose and glucose molecules. LB generates EPS comprised of galactose, glucose and mannose molecules.

Specific “ropy” strains of yogourt starters are available, which generate high levels of EPS and thicken up the yogourt texture. EPS production is a strain related property and also influenced by processing conditions.

Figure 5a.4. Exopolysaccharide production

Figure 5a.5. Microstructure of yogurt

Probiotic Yogourt Cultures

In addition to LB and ST, other cultures such as probiotic strains can be added to yogourt. Main probiotic yogourt cultures are strains of Lactobacillus acidophilus and Bifidobacterium spp., eg. B. longum, B. infantis – known as ”BA cultures”. Bifidobacteria are difficult to grow under normal yogourt conditions due to low proteolytic activity.

The viability of cultures needs to be maintained until point of sale in order to make a probiotic health claim. Bifidobacteria do not grow well below pH 5.0 and so, the final yogourt pH must not drop too low to ensure survival of certain strains of bifidobacteria, which are also sensitive to oxygen. Final yogourt pH may need to be maintained at 5.5-5.6 to retain bifidobacteria viability. These conditions may also affect the sensory properties of the final product (less acid, mild, etc.).

What is Kefir?

A milk product made by an acidic-alcoholic fermentation (<0.1% ethanol). It is considered a probiotic product. In the production of Kefir, the inoculum is either (a) commercial freeze dried kefir starter or (b) traditional kefir grains containing a mixed and generally undefined culture. Kefir grains are small granules of 0.3 to 3.5 cm in diameter containing the cultures.

Examples of kefir and kefir grains (thecheesemaker.com)

Kefir grains are composed of around 108 CFU/g of LAB, mainly Lactobacillus, Lactococcus, Leuconostoc and Streptococcus (ST) and around 107 CFU/g of Yeasts (mainly Saccharomyces cerevisiae (beer yeast), S. unisporus, Candida kefyr, and Kluyveromyces marxianus spp. marxianus). Additionally, acetic acid bacteria (Acetobacter aceti and Acetobacter rasens) in quantities close to 105 CFU/g. All these microorganisms are enclosed within a polysaccharide matrix. In the traditional (“Russian”) method the grains are used as the milk inoculum. This traditional method is used by home kefir makers and small processors, while large scale commercial production of kefir involves use of starters as DVI/DVS preparations derived from kefir grains. Adjunct cultures of Bifidobacterium sp., Lactobacillus sp., and Saccharomyces boulardii may also be added.

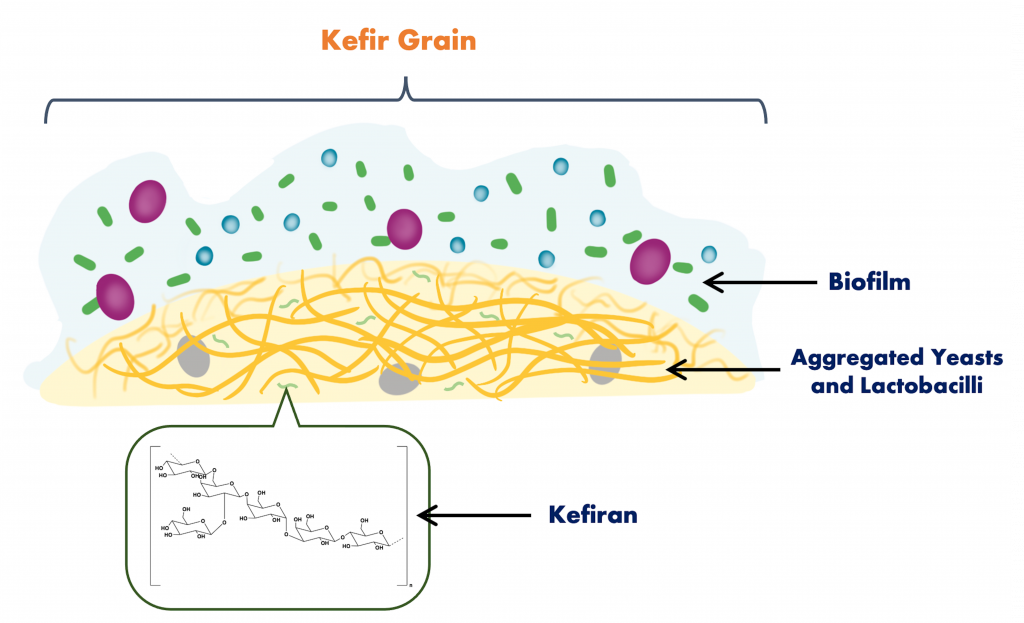

The composition of Kefir grains is complex and is hold together by a matrix of polysaccharides (Figure 5a.6):

- The main polysaccharide is kefiran, made up of 50/50 mix of glucose and galactose produced by Lactobacillus kefiranofaciens (which comprises 80% of all Lactobacillus spp. in Kefir grains). This polysaccharide improves the viscosity or thickness of the milk. Not that much is known about formation of the grains but it appears that the bacteria start to aggregate or clump together to form small granules. As the milk pH drops then aggregation or clumping is enhanced further.

- Next biofilm producers, Lactobacillus kefiri, Kluyveromyces marxianus HY1, and Pichia fermentans HY3 stick to the surface of the small granules and give rise to thin biofilms. After biofilm formation, the kefir yeasts and lactobacilli continue to join the granule to become a very large microcolony. Apart from Lb. kefiranofaciens, LAB species include Lb. paracasei, Lb. acidophilus, and Lb. bulgaricus.

- As the populations of kefir yeasts and lactobacilli increase, cells and milk components deposit onto the granule surface and the kefir grains are formed.

The basic microbiology of kefir is a Symbiotic culture of Yeast and LAB, which are mutually beneficial. Addition of Saccharomyces yeasts stimulates kefiran production by Lb. kefiranofaciens.

Figure 5a.6. Kefir grain structure

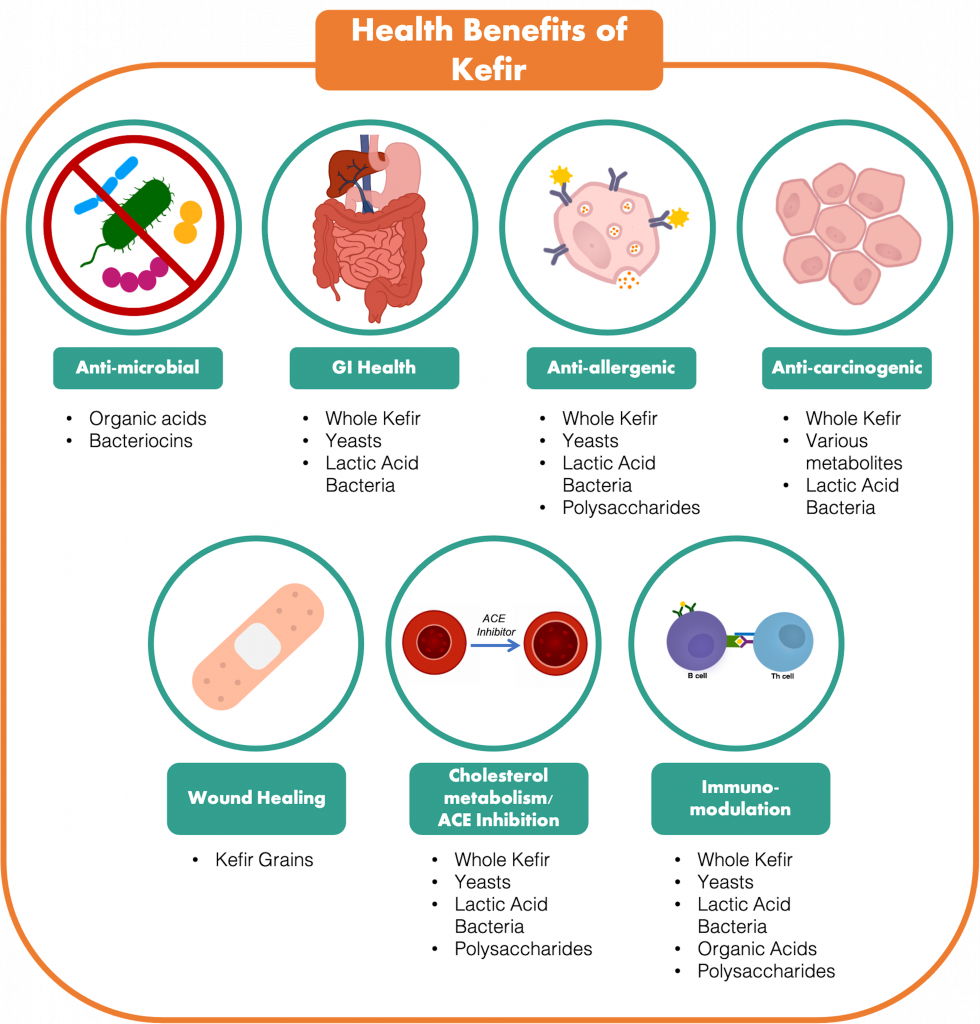

Certain Lb. kefiranofaciens strains have claimed probiotic properties, e.g cholesterol reduction, prevention of cholesterol absorption, anti-allergenic, anticolitis effects, while yeast, such as S. cerevisiae, have exhibited anti-pathogenic activity against Shigella and inhibition of Clostridium difficile toxins. Yeast also generate B vitamins and CO2 gas and alcohol, which affects the flavour and texture of kefir.

The kefiran molecule has biological activities (Figure 5a.7) including:

- Anti-hypertensive effects

- Anti-tumor

- Anti-microbial

- Increased IgA (stimulates immune system)

- More rapid wound healing

Figure 5a. 7. Health benefits of kefir (Adapted from Bourrie et al., 2014)

Kefir: Flavour components

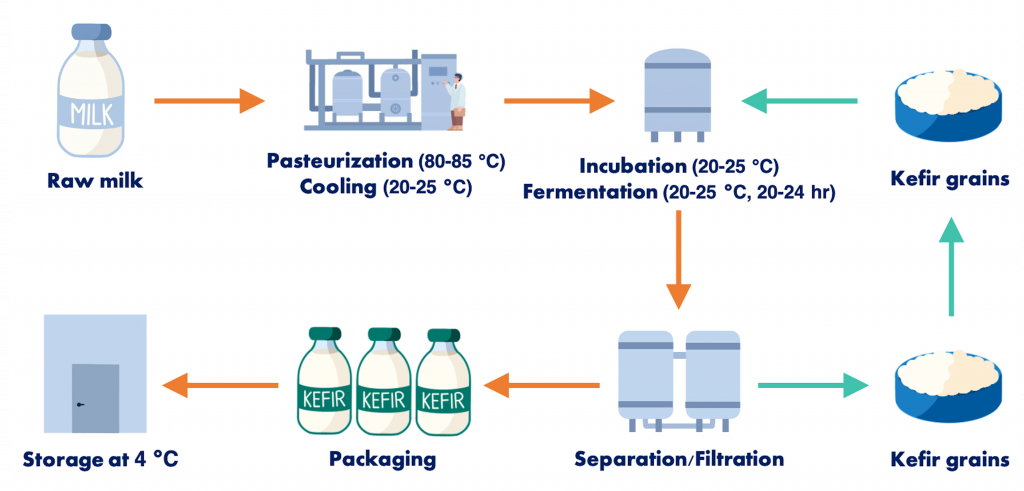

Kefir production

- adding kefir grains to milk, added at a ratio of 1:20

- allowing to ferment for ~24 hours at ~20 οC

- straining of product to recover the kefir grains for re-use for the next batch

- retention of the fermented milk as kefir for drinking

Figure 5a.8. Kefir Production (Adapted from Shen et al., 2018)

Grains or DVS/DVI cultures as starters

Use of kefir grain as starters might be considered as a matter of tradition and cost savings. However, use of grains as starters might have many drawbacks, for example lack of consistency since the composition of the microbes can change on repeated use and lack of stability since the repeated use of grains may lead to die-off of certain strains and species over time. All these problems are reduced by using DVS/DVI culture formats instead of grains, this is the reason why large commercial processors of Kefir are now preferring use of DVS/DVI cultures.

Some Adjunt cultures like Bifidobacterium sp., Lactobacillus sp. and probiotic yeast (Saccharomyces boulardii) may be blended with kefir grains or kefir DVI cultures. Most freeze dried industrial cultures for kefir contain a mix of Lactococcus spp., Leuconostoc spp., Streptococ[1]cus thermophilus, Lactobacillus spp., and kefir yeast, for example the FD-DVS EXACT Kefir 2 (Chr. Hansen Inc. Denmark).

Kefir Quality

References

Bourrie, B. C., Willing, B. P., & Cotter, P. D. (2016). The Microbiota and Health Promoting Characteristics of the Fermented Beverage Kefir. Frontiers in microbiology, 7, 647. https://doi.org/10.3389/fmicb.2016.00647

Kaur, R., Kaur, G., Rima, Mishra, S. K., Panwar, H., Mishra, K. K., & Brar, G. S. (2017). Yogurt: A Nature’s Wonder for Mankind.. International Journal of Fermented Foods, 6(1), 57-69. doi: 10.5958/2321-712X.2017.00006.0.

National Dairy Code, 1997 – Part II and III (amended July 2005)

Shen Y., Kim D.-H., Chon J.-W., Kim H., Song K.-Y., & Seo K.-H. (2018). Nutritional Effects and Antimicrobial Activity of Kefir (Grains). J. Milk Sci. Biotechnol, 36(1), 1-13. https://doi.org/10.22424/jmsb.2018.36.1.1

Colony Forming Unit per gram

cultures that are added to develop acidity and some main by-products (e.g. CO2)

a mechanical process that mixes milk fat by passing milk through a small orifice using high pressure

a heat treatment process used to kill harmful pathogens in milk and milk products that can cause diseases, such as tuberculosis and typhoid fever

an enzyme that catalyzes the breakdown of fats in a process called lipolysis

outlines health rules for the production and market placement of raw milk, heat-treated milk and milk-based products

high temperature, short time

ultrahigh temperature

an enzyme naturally present in raw milk, which is completely inactivated at a temperature close to the pasteurization temperature of milk

a piece of equipment used to transfer heat between fluid products

refers to the separation or expulsion of whey from the gel matrix, also called syneresis

enzyme that catalyzes the breakdown of lactose into glucose and galactose

live microorganisms that may impart health benefits when consumed in adequate amounts

Proto-cooperation is where two species interact with each other beneficially and they interact only for the gain that they receive from doing this. Note that growth and survival is possible in the absence of the interaction, but they do it better with the interaction.

volatile compound with an ethereal, fresh, green and pungent odour

volatile compound with a buttery, creamy and vanilla-like odour

volatile compound with a buttery odour

volatile compound with a buttery, vanilla and mild odour

refers to the breakdown of proteins into smaller peptides or amino acids

Lactic acid bacteria

Direct vat inoculation or direct vat set cultures are freeze-dried starter cultures that can be directly added to milk

having a close relationship or interaction between two or more organisms