Dairy Products

27 Overview and Fluid Milk Products

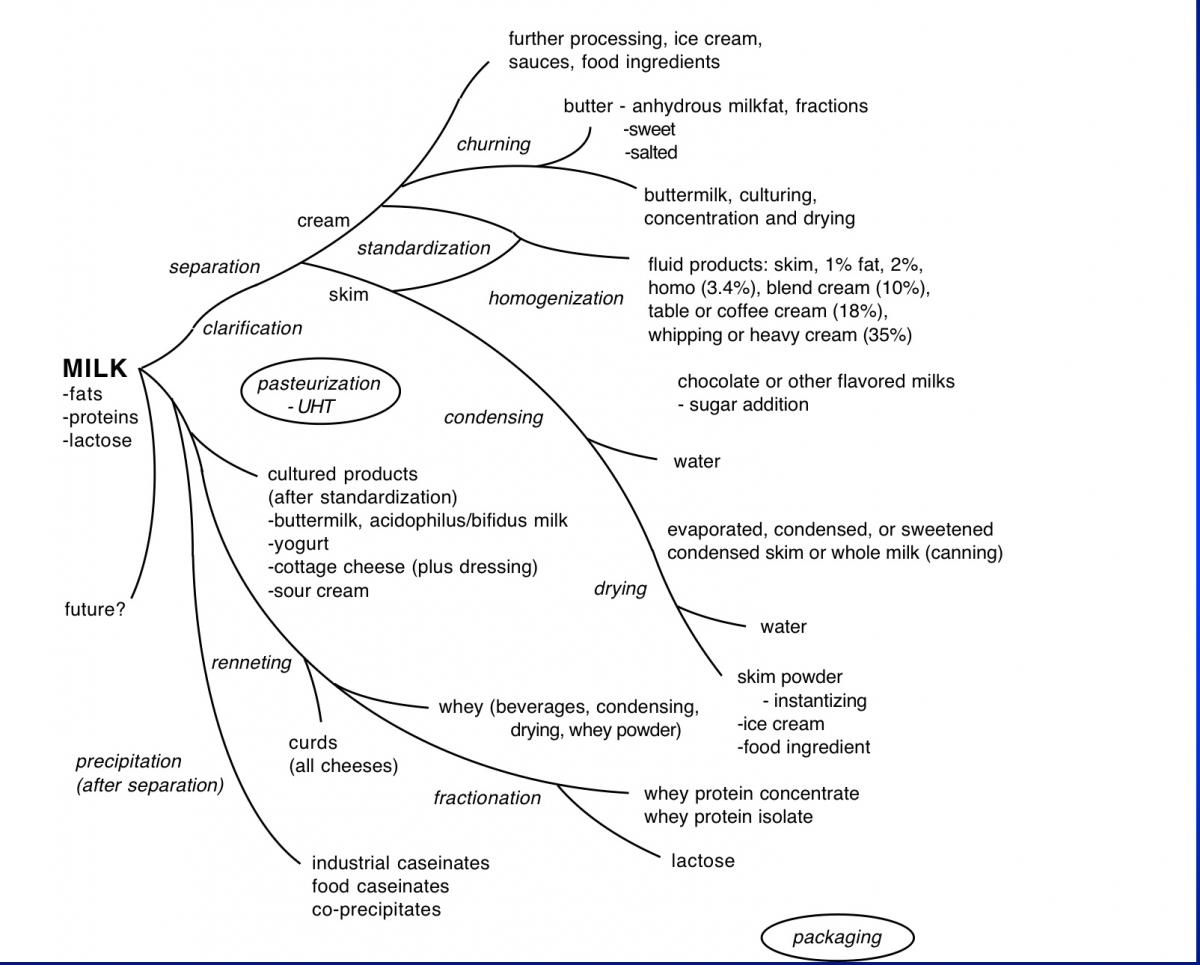

Overview of the Range of Products that can be Manufactured from Milk as a Starting Point

Fluid Milk Products and Processing

Beverage Milks

Vitamins may be added to both full fat and reduced fat milks. Vitamins A and D (the fat soluble ones) are often supplemented in the form of a water soluble emulsion to offset that quantity lost in the fat separation process.

Creams

During the separation of whole milk, two streams are produced: the fat-depleted stream, which produces the beverage milks as described above or skim milk for evaporation and possibly for subsequent drying, and the fat-rich stream, the cream. This usually comes off the separator with fat contents in the 35-45% range. Cream is used for further processing in the dairy industry for the production of ice cream or butter, or can be sold to other food processing industries. These industrial products normally have higher fat contents than creams for retail sale, normally in the range of 45-50% fat. A product known as “plastic” cream can be produced from certain types of milk separators. This product has a fat content approaching 80% fat, but it remains as an oil-in-water emulsion (the fat is still in the form of globules and the skim milk is the continuous phase of the emulsion), unlike butter which also has a fat content of 80% but which has been churned so that the fat occupies the continuous phase and the skim milk is dispersed throughout in the form of tiny droplets (a water-in-oil emulsion).

For retail cream products, the fat is normally standardized to 35% (heavy cream for whipping), 18% or 10% (cream for coffee or cereal). Higher fat creams have also been produced for retail sale, a product known as double cream has a fat content of 55% and is quite thick. Creams for packaging and sale in the retail market must be pasteurized to ensure freedom from pathogenic bacteria. Whipping cream is not normally homogenized, as the high fat content will lead to extensive fat globule aggregation and clustering, which leads to excessive viscosity and a loss of whipping ability. This phenomena has been used, however, to produce a spoonable cream product to be used as a dessert topping. Lower fat creams (10% or 18%) can be homogenized, usually at lower pressure than whole milk.

Whipped Cream Structure

As the fat partially coalesces, it causes one fat-stabilized air bubble to be linked to the next, and so on. The whipped cream soon starts to become stiff and dry appearing and takes on a smooth texture. This results from the formation of this partially coalesced fat structure stabilizing the air bubbles. The water, lactose and proteins are trapped in the spaces around the fat-stabilized air bubbles. The crystalline fat content is essential (hence whipping of cream is very temperature dependent) so that the fat globules partially coalesce into a 3-dimensional structure rather than fully coalesce into larger and larger globules that are not capable of structure-building. This is caused by the crystals within the globules that cause them to stick together into chains and clusters, but still retain the individual identity of the globules. Please see a further description of this process for details. If whipped cream is whipped too far, the fat will begin to churn and butter particles will form.

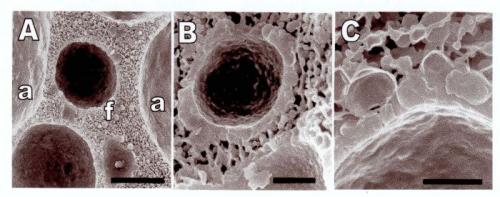

Below are scanning electron micrographs image of whipped cream. If you compare the schematics above with the “real thing” below, you should be able to fully understand whipped cream structure.

The structure of whipped cream as determined by scanning electron microscopy. A. Overview showing the relative size and prevalence of air bubbles (a) and fat globules (f); bar = 30 um. B. Internal structure of the air bubble, showing the layer of partially coalesced fat which has stabilized the bubble; bar = 5 um. C. Details of the partially coalesced fat layer, showing the interaction of the individual fat globules. Bar = 3 um.

Recombined Milk

Chocolate Milk

- 93% milk

- 6.3% sugar

- 0.65% cocoa powder

- 0.05% carrageenan

The final product is usually standardized to either 2% fat or 1% fat (meaning, 2.15% or 1.1% fat in the milk before addition of other ingredients). The sugar, cocoa powder and carrageenan are dry blended, and added to cold milk with vigorous agitation, and then pasteurized.