Milk

10 Treatment of Milk for Cheese Making

1. Clarification

Clarification may be as simple as filtering out debris or may include standardization of micro flora by removing microbial cells and spores. The principal clarification/standardization procedures are as follows.

- Cloth filters are common to remove debris at the farm but are not necessary at the processing plant.

- Centrifugal clarifiers may be used to remove particles which escape filtration. Cream separators effectively double as centrifugal clarifiers because small particles of debris collect at the periphery of the separator bowl and are ejected as sludge. The loss of milk solids by this process is minimal.

- Bactofugation is a high speed centrifugal process that separates bacterial cells and spores. Bactofugation is used most commonly in Europe to prevent late gas formation in Dutch and Swiss type cheeses. Bactofugation removes 95% of the spores of milk which means the risk of late gas defect due to germination and growth of Clostridium tyrobutyricum is much reduced, but not eliminated.

- 1 ‑ 2% of milk solids is transferred to the bactofugate. To avoid yield loss, the bactofugate which contains 12 ‑ 16% dry matter, is sterilized by ultrahigh temperature processing and added back to the milk.

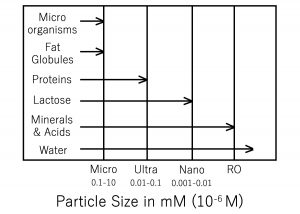

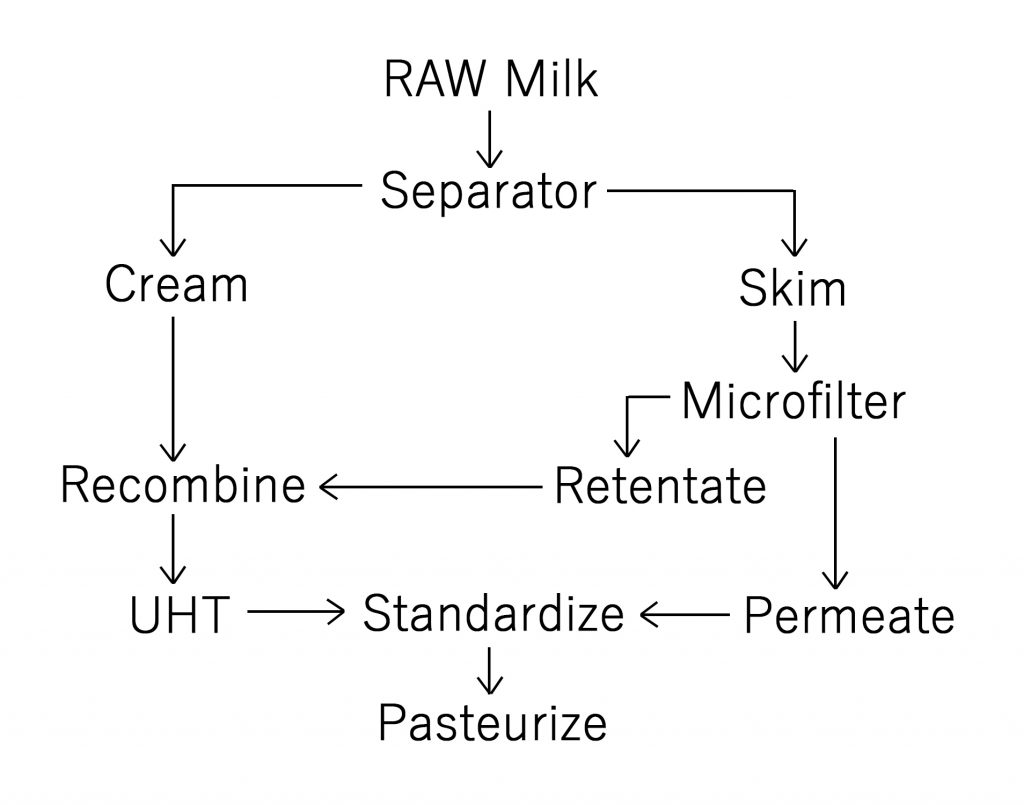

- Microfiltration, a membrane process, has been used to clarify milk since the early 1980s. Think of microfiltration as an ultrafine sieve. Microfiltration and related membrane processes are illustrated in Figures 10.1 and 10.2 and further described in Part 24. Microfiltration achieves about 99% reduction of spore forming bacteria relative to 95% by bactofugation. The disadvantage is that microfiltration can be applied only to skim milk because the milk fat globules are too large to pass through the microfiltration membrane (See Figure 10.2).

Figure 10.1. Membrane concentration/fractionation: microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. The terms used in this figure will be explained in Section 7.2.1.

2. Heat Treatments

Many people assume that all dairy products in Canada, including cheese, are made from pasteurized milk. This is not the case, as several alternatives are possible as outlined below. Note: the Food and Drugs Act and Regulations recognizes only two types of cheese with respect to milk heat treatment, namely, fully pasteurized milk and raw milk. That is, if the milk is not fully pasteurized the resulting cheese is considered raw milk cheese.

1. No heat treatment results in raw milk cheese. Raw milk cheese by law must be “held at 2ºC or higher for a period of 60 days or more from the date of the beginning of the manufacturing process” Food and Drugs Act and Regulations, Sections B.08.030 and B.08.043. The question of raw milk cheese is an ongoing concern to consumer groups and to health authorities. Suffice it to say that with respect to regulations on cheese milk heat treatments, “one size doesn’t fit all”.

2. Thermisation (typically 63 ‑ 65ºC, short hold) results in phosphatase positive milk, which must be fully pasteurized before cheese making. The purpose is to prevent raw milk spoilage (e.g. over a weekend) due to acid or protease producing bacteria.

3. Pasteurization (63ºC, 30 min or 72ºC, 16 s) is generally considered the safest alternative, but the full flavour of traditional ripened cheese may not be achieved. Note: that over-pasteurization causes denaturation of whey proteins which subsequently adsorb to the casein particles. The effects are:

- Longer flocculation times

- Weak or no curd formation

- Excessive loss of fines

- Poor syneresis (moisture release)

- Coarse textured curd with reduced ability to stretch, mat and melt.

4. Heat-treat is trade lingo for sub-pasteurization treatments (55 – 65ºC, 16 s) that are applied to destroy most pathogens, but allow some bacteria to survive and contribute to cheese ripening. This process develops fuller cheese flavour with better control of culture growth (i.e., acid development) than with raw milk. For current regulatory purposes, heat-treat is equivalent to raw. Most aged Canadian Cheddar is safely made from heat-treat milk.

3. Homogenization

The process of homogenization reduces milk fat globule sizes from 1 – 15 micrometer (μm) to less than 2 μm (a micrometer is 0.000,001 m). The natural membrane on the fat globule is replaced by milk proteins, mainly caseins. This results in increased interaction between fat globules and the casein particles in the rennet gel. For some cheese, homogenization is desirable:

- Homogenization promotes lipolysis, whitening, and flavour development in cheese made from cow milk that are traditionally made from goat or sheep milk, e.g., Blue and Feta.

- Homogenization increases fat recovery and creates smoother texture in cream cheese.

With respect to most firm/hard ripened cheese, many workers have observed that cheese made from homogenized milk is too tough and firm after pressing. However, there is evidence that homogenization for Cheddar cheese making has the following advantages if medium pressure (6.9 MPa) is used and if only cream (35% fat) is homogenized and subsequently blended with non-homogenized skim milk[1].

- Increased rate of gel firming and higher curd firmness at cutting.

- Increased cheese yield due to greater moisture retention and improved fat and protein recovery.

- Notwithstanding higher moisture content, cheese texture and flavour was not decreased by homogenization.

4. Additives to Cheese Milk

1. Calcium Chloride is frequently added to aid coagulation and reduce amount of rennet required, especially if milk is set immediately after pasteurization. Recommended levels range from 0.005% to 0.020%, usually added as a 30% solution.

2. Nitrates (sodium or potassium nitrate) may be added at levels of about 200 ppm to Edam, Gouda and Swiss types to inhibit growth of gas forming Clostridium tyrobutyricum.

3. Annatto cheese colour is added to some cheese to standardize seasonal changes in colour or to create orange cheese such as Cheddar and Cheshire. The following are some properties of annatto.

- Annatto is a carotenoid similar to β-carotene and Vitamin A in structure, but it has no Vitamin A activity.

- Annatto colour is red to yellow pigment, but it usually appears as orange. The red constituent is more apparent with decreasing pH (6 ‑ 4.8) changing the orange to pink while at pH < 4.5, the pink fades and becomes nearly white. This accounts for “acid‑cut cheese”. Bleaching and pinking of annatto is also caused by oxidizing agents such as copper, iron, chlorine and light.

- Oxidation of annatto is also encouraged by heat, so annatto is an unsuitable colorant for process cheese

- Alternatives to annatto are:

- Beta‑carotene which is too yellow and makes the cheese taste like carrots.

- Apo‑8‑carotenal which has the advantage that relative to annatto it is less soluble in the whey.

4. Decolorants. Goat and sheep milk are flat white in colour because they lack β‑carotene. Cow milk may be whitened to mimic goat or sheep milk. Legal whitening agents include chlorophyll based products that mask the natural yellow colour. Excess chlorophyll makes green cheese.

5. Ripening Agents. A wide range of products are available to accelerate cheese ripening or to develop a broader flavour profile. Relative to traditional cheese varieties, several factors suggest the need for ripening supplements:

- Non-traditional cheese making methods such as:

- Pasteurized or heat treat versus raw milk

- Cows’ milk substituted for the milk of other species

- Traditional rennet pastes containing a wide range of enzymes including lipases and proteases have been replaced with purified extracts

- Cold storage and transport of milk severely alters natural milk micro flora

- Economic pressure to reduce ripening time

- Marketing pressure to standardize quality attributes

6. Lipases (lipolytic enzymes) may be added to cow milk to produce cheese such as Feta, Romano, Kefalotyri, and Parmesan which are traditionally made from raw goat or sheep milk. That’s because goat and sheep milk, especially goat milk, have more natural lipase than cow milk. Commercial lipases are commonly extracted from kid goats.

7. Enzyme cocktails are mixtures of enzymes from various sources added to the milk to accelerate ripening of aged cheeses. They may include both lipases and proteases, with a predominance of proteases for Cheddar. Bacterial enzyme extracts from lactic acid bacteria have also been used. Accelerated ripening is further discussed in Part 14.

- Nair et al. 2000, Int. Dairy Journal 10:647 ↵