Manufacturing, Ripening, Process Control and Grading

16 Defects and Grading

1. Defects

Common Cheese Defects

Body: in the context of modern sensory analysis, body refers to texture, which is confusing because cheese graders use the term “texture” to refer to cheese openness. Here, we will use the traditional cheese grading terms. Some descriptors for body defects are:

- Crumbly/short: often due to excess salt or acid.

- Corky: due to overcooking, low fat, low moisture, or excess salt.

- Mealy: this defect can be detected on the palate or by massaging the cheese between the thumb and forefinger. It is usually associated with excess acidity.

- Pasty: sticks to the palate and fingers; due to excess moisture.

- Weak: breaks down too quickly when worked by hand due to excess fat or moisture.

Texture: relates to openness in the cheese which may or may not be desirable depending on the type of cheese and the cause of openness. Openness can be due to:

- Mechanical openings, which are holes of irregular shape caused by trapped whey. Trapped whey makes the impression in the cheese during pressing, but during ripening the moisture is dispersed throughout the cheese leaving the hole behind. Mechanical openings can lead to discolouration around the opening due to local acid development. Undesired mechanical openings can be reduced or closed by vacuum packaging.

- Gas holes, which are desirable in many types of cheese. Gas hole defects include:

- Early gas defects due to coliforms. These appear as small, spherical, shiny holes. The defect is often associated with unclean flavour.

- Late gas due to Clostridium tyrobutryricum or perfringens, especially in some European made cheese. Clostridia spores are often present in American cheese as well but do not normally cause problems. However, they may be activated by heat treatment and therefore, sometimes cause gas defect in processed cheese.

- A third gas defect occurs in Cheddar and American types. The defect is distinctive in that the gas (mainly CO2 with some hydrogen sulphide) blows the package but not the cheese. The defect occurs at 6 – 9 months in Cheddar, but a similar defect is sometimes observed earlier in American Mozzarella and Colby. The causative anaerobic organism is not fully identified; however, experiments have demonstrated that the defect does not occur in cheese aged at < 10°C.

- Yeast slits due to yeast growth.

Flavour: most grading systems assign the greatest weight to flavour defects. A few common descriptors are:

- Acid flavour is often associated with acid body defects noted above. The common causes all relate to process control:

- Too much moisture (i.e., too much lactose).

- Too much starter (i.e., too much acid development before draining).

- Salting too late or too little.

- Too warm during or immediately after pressing.

- Bitter flavours are common defects in American but also other cheese, including fresh cheese. Some causes include:

- High moisture

- Excess rennet

- Bitter cultures

- High ripening temperatures

- Fruity/Yeasty flavours are usually associated with high pH and bitterness, and sometimes with yeast slits.

- Unclean flavours are reminiscent of the barnyard, and may be associated with coliforms.

- Whey taint is due to high moisture and is usually associated with acid defects including bitterness.

Colour: other than traditional colour preferences, such as orange Cheddar and white goat cheese, the most important colour parameter is uniformity. Even for cheese such as Colby, which is coloured with annatto, graders do not evaluate colour intensity. Rather, they look for non-uniformity, which may signal a manufacturing defect. Some common descriptors are:

- Acid cut (pink or bleached): low pH, oxidation of annatto.

Bocconcini cheese with blue discolouration. - Mottled: may be an acid defect or caused by mixing cheese from different vats.

- Seamy: this is a Cheddar defect where the curd particles fail to knit properly. Causes Include:

- Greasy curd from too much fat or high temperature during pressing.

- Improper salting, too soon after milling or pH at salting is too high or too low.

- Hooped too soon after salting.

Finish: a lot of art and patience are required to produce cheese with a good finish. Common defects are:

- Checked/Cracked: too dry on surface.

- Greasy: temperature too high during pressing or curing.

- Huffed: gassy.

- Mineral Deposits due to calcium lactate.

- Common on Cheddar cheese and sometimes on American varieties

- Encouraged by certain non-starter Lactobacilli and Pediococci which favour formation of D-lactate which in turn encourages crystallization of DL-calcium lactate.

- Control measures are:

- Decrease numbers of non-starter bacteria (e.g., pasteurize versus heat treat and/or bactofuge the milk).

- Use tight packaging. Calcium lactate crystals tends to form in areas where the package is loose or in depressions on the cheese surface.

- Avoid temperature fluctuations. Calcium lactate crystals often form in the dairy case where temperatures are not constant.

- Encourage rapid turnover in the dairy case.

- Rind rot caused by mites or mold.

- Surface mold is definitely one of the most common defects. A frequent consumer question is about the safety of moldy cheese.

- Unsymmetrical/Rough: poor workmanship.

2. Grading

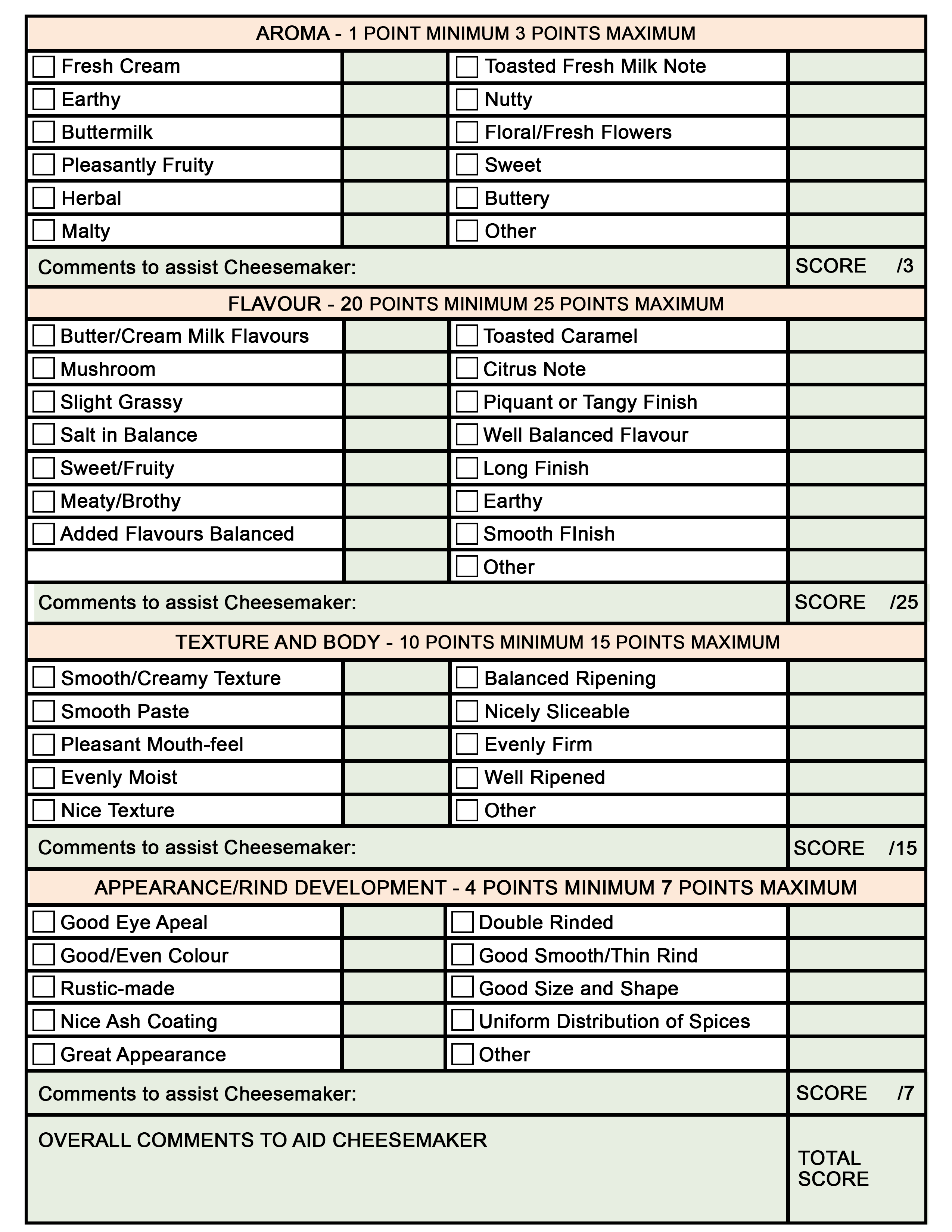

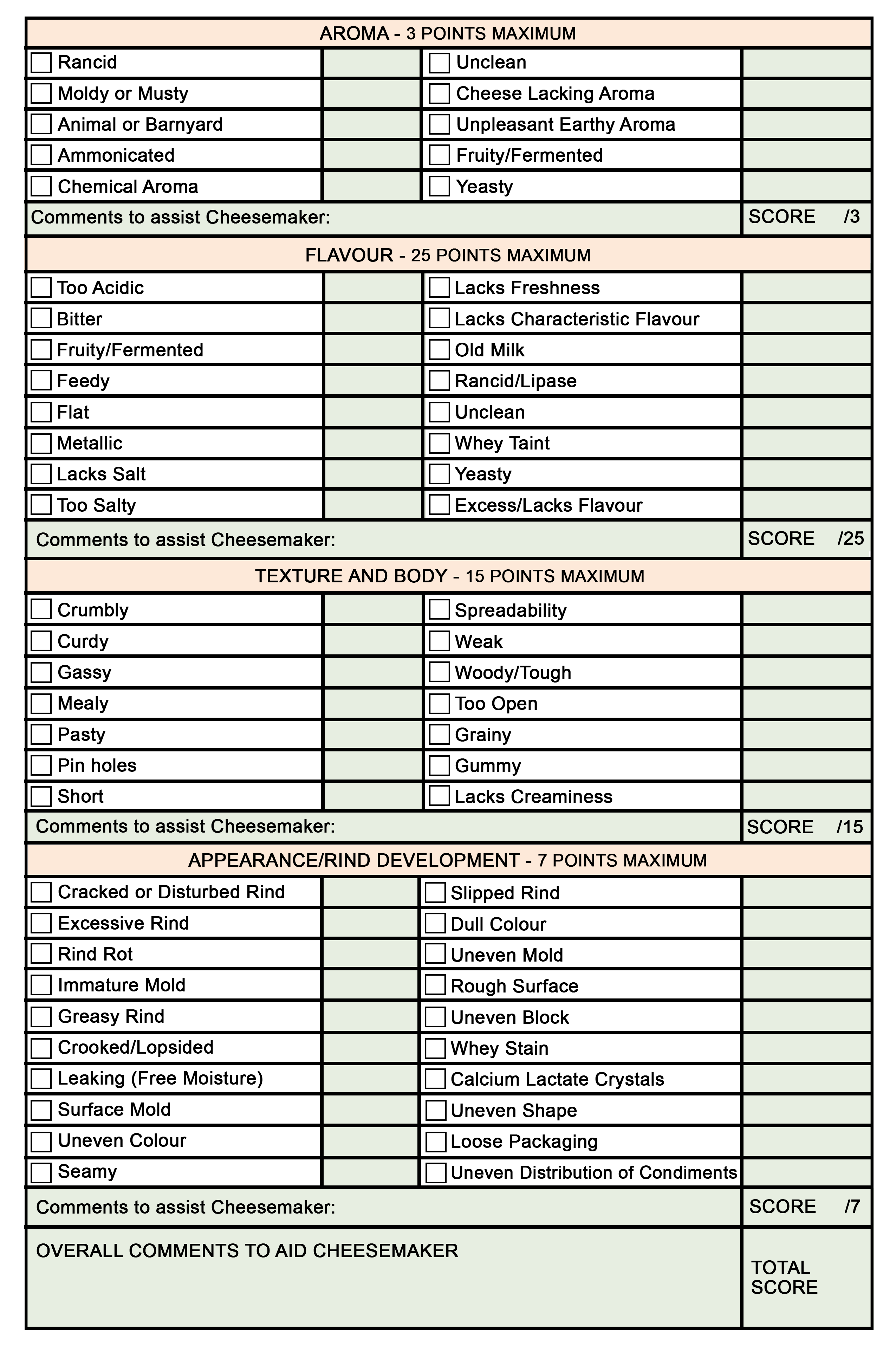

The following cheese grading score sheets are adapted from the American Cheese Society and are included as examples only. Tables 16.1 and 16.2 show the glossaries of the respective technical and aesthetic grading terminology and descriptors used to grade cheese for the 2018 Canadian Cheese Awards, with definitions adapted from the American Cheese Society. Figures 16.1 and 16.2 are two parts of a single score card. Both of these score cards are defect-based evaluation, where the judge starts with a maximum score for each category and deducts points for each identified defect. Currently, many cheese competitions have Aesthetic and Technical judges working in teams, as in the score card example of Figure 16.1 and 16.2. Aesthetic judges add points for desirable properties (Figure 16.1); and Technical judges deduct points for defects (Figure 16.2). The two scores are summed to give a total score out of 100.

Table 16.1: Glossary of Terms for Judging Cheese

| Aroma | |

| Lipase or rancid | Means a bitter or disagreeable odour suggestive of butyric acid and derived from decomposed milk fat |

| Moldy or musty | Musty aroma |

| Barny | Characteristic of the odour of the milking barn, stable or cow yard |

| Ammoniated | Aroma associated with Ammonia (e.g. cat pee) |

| Chemical | Aroma associated with chemicals |

| Unclean | Unclean or unpleasant odour |

| Lacking cheese aroma | Lacking cheese aroma characteristic of the variet |

| Unpleasant earthy aroma | Sometimes described as “cave-y”, “dirt-like”, or “basement-like”. May be difficult to distinguish from musty odours |

| Fruity | Sweet fruit-like aromas resembling apples and generally increases with intensity as the cheese ages (undesirable) can also include pineapple, strawberries and other fruit aromas |

| Yeasty | Yeasty smell reminiscent of bread or beer, an aroma indicating the presence of yeast fermentation in the manufacture of the cheese |

| Flavour | |

| Acidic | Cheese is sharp, puckery to the taste (lactic acid) |

| Sour | Vinegar-like flavour, different from acidic |

| Bitter | Distasteful flavour of quinine; often found in aged cheese varieties and/or associated with excessive moisture. Noted primarily on the back of the tongue |

| Fermented fruit | Fermented whey or fermented (spoiled) fruit smell |

| Feed, weedy, or green | Presence of one or more feed flavours such as weeds, alfalfa, sweet clover, silage or similar feed, carried through the milk into the finished product |

| Metallic | Flavor trait suggestive of metal (copper, iron) that imparts to the mouth a puckery, tangy sensation |

| Lacks salt | Lacks salt for the variety |

| Too salty | Too much salt for the variety |

| Lacks freshness | Lacks freshness characteristic of the cheese variety |

| Lacks flavour | Lacks flavour characteristic of the cheese variety |

| Old milk or stale | Means a cheese flavour indicating a lack of freshness in the milk used in manufacturing the cheese |

| Lipase or rancid | Means a bitter or disagreeable taste or odour suggestive of butyric acid and derived from decomposed milk fat |

| Unclean | Unclean flavour; lingering aftertaste |

| Whey taint | Slight sweet-acidic flavour and odour of fermented whey caused by too slowly or incompletely drained curds |

| Yeasty | Flavour associated with the presence of yeast, including fermented, whey tainted and malty |

| Unbalanced (FL) | Flavour too strong or too weak or not compatible with the cheese. The flavour either hinders the cheese flavour or does not contribute to an extra noticeable flavour |

| Texture | |

| Crumbly | Cheese is loosely knit and tends to fall apart when rubbed between the thumb and fingers |

| Curdy | Cheese is smooth but firm; if worked between the fingers, it is rubbery, not waxy |

| Gassy | Cheese contains gas holes of various sizes, which may be scattered or unevenly distributed throughout the cheese. Slits are also signs of gas formation (cheese matrix splits instead of forming round eyes) |

| Mealy | Cheese has a short body texture, does not mold well; may be associated with corky |

| Pasty | Cheese has a weak body, and it becomes sticky and smeary when rubbed between the thumb and fingers |

| Pin holes or Pinny | The presence of numerous and very small gas holes in a cheese |

| Short | There is no elasticity to the cheese plug removed by means of a grading trier, and the plug tends toward mealiness when rubbed between the thumb and fingers |

| Spreadability | Too spreadable or insufficiently spreadable according to desirable characteristics of the cheese |

| Weak | Weak, possibly wet, soft, too much whey in the cheese. Such curds often mat down very thin. Curd does not hold up when rubbed between the thumb and finger |

| Corky, woody, tough | Hard, tough and overly firm cheese texture characterized by failure of the cheese to break down when rubbed between the thumb and fingers |

| Too open | Contains irregularly shaped mechanical openings from making process, not gas |

| Grainy | Cheese is rough, dry and sandy to the touch and feels sandy in the mouth |

| Gummy | Firm pasty or gummy-like texture, hard to chew, sticks to teeth and gums |

| Lacks creaminess | Firm: Body of cheese feels solid and is not soft or weak |

| Too firm for variety | Indicated by free fat on the surface or between particles of curd that are not well fused together |

| Greasy | Weak cheese often tends to be pasty. May also be caused by too much fat |

| Waxy | When worked between the fingers, cheese molds like wax or cold butter |

| Closed | Texture of the cheeses has fewer mechanical openings and/or gas holes than is characteristic of the variety |

| Appearance/Rind | |

| Mottled | Uneven color in the cheese, most noticeable in colored cheese |

| Cracked or disturbed rind | Means the presence of openings or breaks in the cheese rind |

| Excessive rind | Thickness of the rind is too much for the thickness of the body of the cheese |

| Rind rot | The presence of soft spots on the rind which have become discolored and have decayed or decomposed |

| Immature mold (BR, BC) | Lack of mold development in bloomy, mixed rinds or blue type cheese |

| Greasy rind | Presence of free fat on the rind |

| Crooked Lopsided | Cheese is markedly asymmetrical or higher on one side than on the other side |

| Leaking free moisture | Seen as water or liquid droplets on the surface |

| Surface mold | Mold occurring on the paraffin or exterior surface of the cheese |

| Seamy | The presence of white thread-like lines that form if the pieces of curd are not properly fused together. These lighter lines follow the borders of curd pieces |

| Slipped skin or toad skin (BR) | The rind has detached or slipped from the main cheese due to excessive softness under the rind. Rind may appear bumpy with mottled discoloration. Caused by too much moisture in the cheese, too high humidity in ripening incubator, or too rapid mold growth |

| Dull, dead or faded colour | Bleached appearance in color. May be caused by pH < 5.0, or exposure to light |

| Rough surface | The exterior of the cheese lacks smoothness |

| Uneven block | A block that is not symmetrical |

| Calcium lactate crystals | Very fine white crystals on the surface of the cheese and less frequently in the interior |

| Uneven shape, Lopsided | Means the cheese style is asymmetrical or higher on one side than on the other sid |

| Loose packaging | The wrapper or film surrounding the cheese is not completely sealed |

| Uneven distribution of condiments (FL) | The condiments do not look evenly distributed around the whole piece of cheese |

| Crooked cheese | Overly lopsided wheel |

| Mold under paraffin, bandage or wrapper | Mold under paraffin, bandage or wrapper |

Terms with a parenthesis are specific for those cheese categories listed in the ( ), where:

F = Fresh, FL = Flavoured, BR = Bloomy rind, BC = Blue cheese

American Cheese Society, Stephanie Clark, Craig Gile, Vince Razionale, Bill Rufenacht, and Sarah Spira, eds. American Cheese Society Cheese and Dairy Product Lexicon and Glossary. Denver: American Cheese Society. Version 1 Published February 1, 2018.; Wisconsin Statute. Cheese Grading, Packaging, and Labelling, ATCP 81.01 35.93 §. Accessed January 3, 2018. Available at: https://docs.legis.wisconsin.gov/code/admin_code/atcp/055/81.

Table 16.2 Glossary of Terminology for Aesthetic Cheese Judging at the 2018 Cheese Awards

| Aroma | |

| Earthy (F) | A flavour or aroma which is a result of the slight mustiness from the feed of the animal or characteristic of the earth where the cheese was made |

| Buttermilk | Typical aroma of buttermilk |

| Fruity (F) | Flavour or aroma reminiscent of fresh apples, pineapple, strawberries and other fruits |

| Herbal | Aroma of fresh herbs (coming from cheese, not added) |

| Toasted fresh milk note | Aroma of recently heated milk |

| Nutty | General term associated with the aroma of different nuts |

| Floral/Fresh flowers | Could be Rosy or Piney, the latter associated with pine trees, or resinous herbs |

| Sweet | Sweet aroma of maple, burnt sugar, or pineapple |

| Buttery | Typical aroma of butter |

| Flavour | |

| Butter/cream | Rich milk fat flavour, typical of fresh butter |

| Mushroom | Flavour or aroma reminiscent of mushrooms |

| Slight grassy | Pertains to flavour or aroma reminiscent of clean green grass or pastoral notes which are the result of the grasses eaten by the lactating animal |

| Toasted Caramel | Slight sweet cooked or caramel flavour note |

| Citrus note | Flavour or aroma similar to the tart, herbal character of lemon; pertains to fresh soft goat cheese |

| Tangy finish or Piquant | A bright, tangy sharp flavour characteristic of hard Italian cheeses |

| Added flavours in Balance with cheese flavour (FL) | Added flavouring compliments the flavour of the cheese and does not over power the flavour of the cheese |

| Nice Balance of Flavours | Milk-based flavours and acid level in the cheese is correctly proportional |

| Salt in Balance | Salt in Balance with all other flavours |

| Sweet/Fruity | Can refers to a particular sweet flavour coming from ripening or the natural sweetness of milk (for example, in Ricotta). Can also refer to the lack of acidity. |

| Meaty/Brothy | Like rich beef broth |

| Long Finish | Pleasant lingering flavour |

| Smooth Finish | Clean, pleasant flavour experience |

| Texture and Body | |

| Smooth/creamy texture | Rich, soft, and spreadable |

| Smooth paste | Smooth interior portion of a cheese |

| Pleasant mouthfeel | Smooth, uniform breakdown of the cheese while chewing it |

| Nice texture | Pleasant texture characteristic of the variety |

| Balance ripening | Uniform appearance and texture throughout the cheese |

| Nicely Sliceable | Slice stays intact and does not crumble |

| Evenly moist | Uniform moisture and soft body throughout the cheese |

| Evenly firm | Relatively inelastic and unyielding texture throughout the cheese |

| Well ripened (BR and BC) | Nice ripening effects of moulds in the interior texture of bloomy rinds and blue cheeses |

| Good openness | Uniform small eyes in Dutch and Swiss cheeses. Uniform mechanical openings in the body of Feta and hard Italian grating cheese. |

| Appearance/Rind Development | |

| Great appearance | Outstanding pleasing appearance |

| Good even colour | Good uniform colour on the exterior and interior of the cheese |

| Rustic/Artisanal appearance | A cheese that is obviously hand-crafted |

| Nice ash coating | Desirable ash coating of some cheese |

| 8.5. Double rinded | Good uniform coverage of both blue and white molds on surface of the cheese |

| Good smooth thin rind | Desirable thin rind on brie and camembert |

| Good size and shape | Attractive, symmetrical shape and uniform size of smaller cheese |

| Uniform Distribution of spices or condiments (FL) | For flavoured cheese |

| Even and smooth Wax or Bandage | Cheese is uniformly wrapped in bandage or parafilm or cheesecloth |

Terms with a parenthesis are specific for those cheese categories listed in the ( ), where:

F = Fresh, FL = Flavoured, BR = Bloomy rind, BC = Blue cheese

American Cheese Society, Stephanie Clark, Craig Gile, Vince Razionale, Bill Rufenacht, and Sarah Spira, eds. American Cheese Society Cheese and Dairy Product Lexicon and Glossary. Denver: American Cheese Society. Version 1 Published February 1, 2018; Wisconsin Statute. Cheese Grading, Packaging, and Labelling, ATCP 81.01 35.93 §. Accessed January 3, 2018. Available at: https://docs.legis.wisconsin.gov/code/admin_code/atcp/055/81.

Notes:

- Cheese should be held overnight at 14.5 – 15.5°C before grading.

- Cheese samples should be 9 Kg in weight.

- Cheese should be at least 21 days old before grading.

- Early evaluation of aging potential can be obtained by grading a sample stored at 15°C for 21 days.

Common Descriptors used in Grading Canadian Cheddar Cheese

- Sl. open, sl. stiff, sl. coarse, blurred branding, sl. damp end, sl moldy surface.

- As above plus slight acid tendency.

- Weak, open, coarse, wet ends, sl. acid, sl. gas or pin holes, mottled colour etc.

- Checked rinds with mold penetration. Sl. gas or pin holes. Any above defect plus a second defect except weak and open.

- Very weak, very acidy, very stiff, very open, gas or Swiss holes (always 3rd), very uneven colour, very mottled.

- Checked rinds, mold penetration, gas or Swiss holes (always 3rd).

Figures 16.1 and 16.2 below show a technical cheese judging score card. The technical score judging card is similar to the traditional defect based grading, which deducts points for defects in each category. Most current cheese judging employs both a technical and an aesthetic judge. The technical judge sums the points for each category to obtain a total score out of 50. This score is then added to the aesthetic score (see Figure 16.1) for a total score out of 100.

When defects are detected, points are deducted. The main categories for scoring are aroma, which yields 3 points maximum, flavour, which yields 25 points maximum, texture and body, which yields 15 points maximum, and lastly, appearance and rind development, which yields 7 points maximum. Under the category of aroma, the defects include: rancid, unclean, moldy or musty, cheese lacking aroma, animal or barnyard, unpleasant earth aroma, ammoniated, fruity or fermented, chemical aroma, and yeasty. Under the category of flavour, defects include: too acidic, lacks freshness, bitter, lacks characteristic flavour, fruity/fermented, old milk, feedy, rancid/lipase, flat, unclean, whey taint, lacks salt, yeasty, too salty, and excess or lacks flavour. Under the category of texture and body, defects include: crumbly, spreadability, curdy, weak, gassy, woody/tough, mealy, too open, pasty, grainy, pin holes, gummy, short, and lacks creaminess. Under the appearance and rind development category, defects include: cracked or disturbed rind, slipped rind, excessive rind, dull colour, rind rot, uneven mold distribution, immature mold, rough surface, greasy rind, uneven block, crooked/lopsided, whey stain, leaking with free moisture, calcium lactate crystals, surface mold, uneven shape, uneven colour, loose packaging, seamy, and uneven distribution of condiments. At the bottom of the sheet, there is an area for graders to provide overall comments to help the cheesemaker. There is also an area to put the total score.