Acidification and Coagulation

12 Cultures

1. General Functions of Cheese Cultures

Lactic acid bacteria and other microorganisms are present as “contaminants” in cheese milk and further environmental contamination takes place during cheese manufacture. Provided the milk is not chilled, it is possible to make cheese without any additional cultures, but normal practice is to add domestic cultures for the manufacture of cheese from both raw and pasteurized milk. Culture, then, refers to prepared inocula of bacteria, yeasts and molds which are added to cheese milk and/or to the cheese at various stages of cheese making. In the broadest terms cultures have two purposes in cheese making: (1) to develop acidity, and (2) to promote ripening. Lactic acid cultures contribute to both of these functions, while numerous special or secondary cultures are added to help with the second function.

Development of Acidity

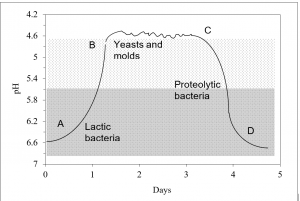

Raw milk at warm temperature will support a variety of microorganisms in succession as the pH changes over time (see illustration in Figure 12.1).

In controlled conversion of milk to fermented dairy products, a primary component of fermentation is development of acidity by lactic acid bacteria. Acid development in cheese making is essential to cheese flavour, cheese texture and cheese safety. Acid is required to:

- Assist coagulation. Lower pH results in faster coagulation and in acid coagulated cheese is the dominant or only factor which induces coagulation.

- Promote syneresis. This is a most critical means to control moisture. Acidity (specifically reduced pH) causes the protein matrix in the curd to contract and squeeze out moisture. That process of contraction is called syneresis.

- Prevent growth of pathogenic and spoilage bacteria. Proper rate and extent of lactic culture growth with associated acid development are critical to the quality and safety of natural cheese. I would argue that with the exception of non-cultured cheese varieties such as ricotta, proper culture growth and acid development is more important than pasteurization with respect to safety. Notice, I did not say that pasteurization is not important!

- Develop cheese texture, flavour, and colour. Generally:

⇐High pH produces soft, soapy, fruity and bitter cheese

Low pH produces cheese with brittle texture and mottled colour⇒

Figure 12.1. A to B. At the natural pH of milk (6.6 – 6.8) and temperatures greater than 20°C, lactic acid bacteria (LAB) rapidly ferment milk sugar (lactose) to lactic acid. Most other bacteria are lactose intolerant. Lactic acid lowers the pH and inhibits most bacteria, eventually including LAB. B to C. Then, acid tolerant yeasts and molds begin to grow and utilize lactic acid, which permits further growth of LAB. This continues until all the lactose is gone. C to D. Yeast and molds are eventually joined by proteolytic bacteria. Together they consume lactic acid or neutralize it with protein break down products. The shaded zones indicate generalized pH tolerance of pathogenic bacteria. Most pathogenic bacteria will grow at pH 5.6 – 7.0 (dark shading); some will grow at pH less than 5.6 (hatched shading); and, some may survive but few will grow at pH less than 4.6 (no shading). Note: that in general terms, all ripened cheese follows this pattern of pH versus time, except that for most predominantly rennet coagulated varieties the minimum pH is greater than 5.0.

Assist Curing

- Growth factors produced by lactic cultures are required for other nonstarter microorganisms which contribute to the desired flavour and body of cheese.

- Enzymes (both lipases and proteases) produced by lactic cultures contribute to interior ripening of cheese and are important to both flavour and texture development.

- Special or secondary cultures are responsible for eye development, surface ripening, etc.

2. Lactic Acid Cultures

General Characteristics of Lactic Acid Cultures

Lactic acid cultures are often called starters or referred to by the acronym “LAB” which stands for lactic acid bacteria. LAB are:

- Non-motile gram positive bacteria.

- Non-spore forming.

- Catalase negative, so, simple tests for catalase activity can be used to identify spoilage bacteria in lactic cultures.

- Microaerophilic or facultative anaerobes, which means they tolerate only low oxygen concentrations.

- Not psychrotrophic, which means that cold storage depletes their numbers and encourages the growth of spoilage bacteria as described in Chapter 4.

- Cocci (spherical cells) 1 μm in diameter OR rods (rod shaped cells) 1 μm wide and 2 to 3 μm long.

Classification of Lactic Acid Cultures

It is helpful to categorize lactic cultures according to general technological and growth characteristics. From that perspective, cultures are grouped by four criteria, namely:

- Principal metabolites (end products of fermentation)

- Optimum growth temperatures: mesophilic versus thermophilic

- Starter composition

- Forms of inoculation

Principal Metabolites: Homo- versus Heterofermentative

Homofermentative means that lactic acid is the principal metabolite with minimal production of gas (CO2) and flavour compounds. Heterofermentative means that lactic acid is the principal end product of fermentation, but technologically significant amounts of one or more of the following metabolites are also produced.

- Carbon dioxide (CO2) which causes the desirable small gas holes in Havarti, Gouda and other cheeses. Gassiness in some cheese varieties is a defect.

- Short chain fatty acids such as acetic acid and propionic acid.

- Acetaldehyde, a principal component of yoghurt flavour.

- Diacetyl, a principal flavour note in sour cream, butter milk, Dutch cheese and Havarti cheese.

- Ethyl alcohol (only relevant to mixed cultures containing yeasts).

Optimum Growth Temperatures: Mesophilic versus Thermophilic

Mesophilic cultures prefer medium range temperatures, rather than cold temperatures (psychrophilic) or hot temperatures (thermophilic).

- Optimum growth range for mesophilic cultures is 30 ‑ 35ºC.

- Acid production is slow or absent at temperatures less than 20ºC.

- Growth is inhibited at temperatures greater than 39ºC.

- Generally, any cheese which does not require high temperatures to dry the curd will utilize mesophilic cultures. These include Cheddar, soft ripened cheese, most fresh cheese, and most washed cheese.

- Mesophilic cultures include both homo- and heterofermentative cultures.

Thermophilic cultures are defined by their ability to grow at temperatures above 40ºC. With respect to cheese making, their important characteristics are:

- Optimum growth in the range of 39 – 50ºC.

- Survive 55ºC or higher.

- Minimum growth temperature is about 20ºC. Cell counts decrease rapidly at colder temperatures, so bulk thermophilic cultures should not be stored at temperatures less than 20ºC.

- Thermophilic starters are normally mixtures of cocci and rod cultures, which at the time of inoculation are about equal in numbers. Rod/cocci blends grow together in a relationship referred to as “mutualism,” where the growth rate and acid production of the mixed cultures are faster than for either culture on its own. The rods produce amino acids and peptides that stimulate the growth of cocci, and the cocci produce formic acid that is required by the rods.

- The balance between the rods and cocci can be controlled by temperature and pH

- The cocci prefer higher temperatures (optimum about 46ºC) than the rods (optimum about 39ºC).

- The rods are more acid tolerant than the cocci, so, initially, the cocci develop the initial acidity and outgrow the rods. But, as the acidity increases the rods begin to grow faster than the cocci.

- Some thermophilic rod cultures have the ability to ferment galactose as well as glucose which is desirable in some cheese, especially Mozzarella.

- Although thermophilic cultures produce acetaldehyde, a principal component of yoghurt flavour, none of the thermophilic LAB are considered heterofermentative.

Culture Blends

- Tables 12.1 and 12.2 list the Latin names and some properties for some common lactic cultures. Table 12.1 is organized according to mesophilic and thermophilic categories and indicates some properties including lactose metabolism in terms of percent lactic acid produced under defined conditions and the optical isomer of lactic acid produced by each culture. D versus L lactic acid has practical applications; for example, L-lactic acid does not readily precipitate during cheese ripening, but DL mixtures do precipitate, forming white granules on the surface of aging cheese.

- Table 12.2 lists many of the same cultures in Table 12.1, but highlights their classical organization. In this table: O type means mesophilic and homofermentative and LD type indicates cultures that include heterofermentors, typically with one or more O culture. L refers to Leuconostoc mesenteroides subsp. cremoris and D refers to Lc lactis subsp. lactis biovar. diaceylactis . D and L cultures may be used without O cultures but only in low acid applications. The table then lists several thermophilic culture blends and several mixed cultures with both mesophilic and thermophilic cultures. Note that optical lactic acid isomers, D and L, are not to be confused with LD heterofermentative cultures.

Table 12.1: Some mesophilic lactic acid bacteria commonly used in cheese making

| Old Name | New Name | Comments |

|---|---|---|

| Streptococcus cremoris

Streptococcus lactis |

Lactococcus lactis ssp cremoris

Lactococcus lactis ssp lactis |

-As a mixed blend, these two form the most common mesophilic and homofermentative culture. -Used for many low temperature varieties; fresh cheese, Cheddar, American varieties etc. |

| Leuconostoc citrovorum

Leuconostoc lactis |

Leuconostoc mesenteroides spp cremoris

Leuconostoc lactis |

-Heterofermentative cultures; ferment citrate; produce both CO2 and diacetyl. -Often mixed with L. lactis ssp cremoris / lactis for traditional butter and butter milk. -May be used for cheese with small holes. |

| Streptococcus diacetylactis | Lactococcus lactis ssp lactis biovar diacetylactis |

-Hetero culture; ferments citrate; produces both CO2 and diacetyl -Mixed with homofermentative lactococci for cheese with small holes |

Table 12.2: Some thermophilic lactic acid bacteria commonly used in cheese making

| Old Name | New Name | Comments |

|---|---|---|

| Streptococcus thermophilus

Lactobacillus helveticus |

Streptococcus thermophilus

Lactobacillus helveticus |

-Commonly used coccus/rod blend for high temperature varieties, Swiss and Italian -L. helveticus galactose positive, used to reduce browning in Moz, and to promote proteolysis in Cheddar |

| Lactobacillus bulgaricus | Lactobacillus delbrueckii ssp bulgaricus | -Commonly blended with S. salivarius. ssp thermophilus for yoghurt -Alternative to L. helveticus in high temperature cheese |

| Lactobacillus lactis | Lactobacillus delbrueckii ssp lactis | -Alternative to L. helveticus and L. bulgaricus where low acid is preferred as in mild and probiotic yoghurts |

Some Technological Properties of Lactic Acid Cultures

In addition to properties mentioned above, the following list includes other technological properties of importance to cheese making. Note: that many of these technological characteristics are encoded on extra-chromosomal genetic material called plasmids. Plasmids have the disadvantage of being unstable, so characteristics encoded on plasmids are also unstable. The advantage is that plasmids can be transferred to other bacteria so microbiologists can use plasmids to transfer technological properties from one LAB to another.

- Galactose metabolism. The ability to ferment galactose is important for late acid development in Italian cheese and to control browning on mozzarella cheese.

- Proteolytic characteristics that contribute to cheese flavour development.

- Resistance to phage (bacterial viruses).

- The ability to metabolize citrate which is associated with flavour development (diacetyl or butter milk flavour) and gas formation.

- Production of bacteriocins, that is, antibiotics produced by bacteria against other bacteria.

- Resistance to bacteriocins.

- Antibiotic resistance.

Starter Composition

- Pure defined cultures are single strain cultures selected from natural mixed populations for specific properties such as proteolytic characteristics or resistance to phage (bacterial viruses). Pure defined strain cultures:

- may be rotated to avoid phage infection,

- have the advantages of uniform rate of acid development and uniform flavour profiles, and

- may be blended to form a defined mixture that is more resistant to phage, but retains predictable rates of acid development and flavour profiles.

- Mixed cultures are nonspecific blends of cultures, somewhat like a natural ecosystem. Nonspecific culture blends normally have complex systems of phage resistance. A disadvantage is less uniform rate of acid development from vat to vat. Nonspecific blends of mesophilic starters are still common, but thermophilic starters are usually defined cultures.

Forms of Inoculation

Cultures are typically prepared for cheese milk inoculation in one of three formats:

- Traditional starters that need several scale up transfers. This system requires some microbiological facilities and expertise and is only feasible for large plants or perhaps for smaller plants that use nonspecific mixed cultures.

- Bulk set culture. In this system, the culture supplier does all the purification and transfer work, and delivers a bulk set culture that is used to inoculate a bulk culture, which in turn is used to inoculate the cheese milk. Bulk cultures are the norm in medium to large plants because the cost savings are significant.

- Direct-to-the-vat cultures require no scale up at the cheese plant. Concentrated cultures ready to inoculate the cheese milk are supplied directly by the culture supplier.

3. Secondary cultures

In addition to lactic acid cultures, many special or secondary cultures are used to promote specific ripening (both flavour and texture) characteristics.

- Large holes: Propioni bacterium freudenreichii subsp. shermanii

- White molds: Penicillium camembertii, P. caseiocolum, P. candidum, and Geotrichum candidum

- Blue/green molds: Penicillium roqueforti, Penicillium glaucum

- Smears:

- Yeasts and molds

- Various coryneform bacteria including Brevibacterium linens, several species of Micrococci, and several species of Staphylococci

- Ripening adjuncts:

- Bacterial or yeast cultures added in addition to the regular lactic acid cultures

- Attenuated cultures which are not intended to grow but only to contribute their enzymes

4. Culture Production, Distribution, Storage

Commercial Culture Preparation

- Lactic cultures are grown in buffered media to facilitate maximum growth without acid inhibition.

- The cells are concentrated by centrifugation.

- The cell concentrate is fast frozen or freeze dried (lyophilized). Frozen (‑40ºC) or lyophilized cultures can be stored for several months without substantial loss of activity. Lyophilized cultures usually require a longer “lag time,” i.e. time after inoculation and before rapid cell growth.

Culture Practice in The Cheese Plant

Direct to the vat cultures need only to be delivered to the vat under aseptic conditions. The following comments relate to the preparation of bulk culture at the cheese plant.

- Culture preparation should take place in a separate culture room which is kept under positive air pressure with hepa-filtered air (0.2 μm filter).

- All surfaces and equipment must be sterile or sanitized/sterilized with 200 ppm chlorine or other agents such as UV light treatment.

- Alternative culture media are:

- Milk, but care must be taken to avoid rancid milk, mastitic milk, milk containing antibiotics, and milk with high bacteria counts.

- 10 – 12% reconstituted skim milk powder is adequate provided that the powder is tested and certified antibiotic free.

- Whey and reconstituted whey powder may be used, but may not achieve the same cell counts as skim milk (due to less buffer capacity).

- A number of commercially prepared culture media are available. Most of these are based on milk protein powders.

- Culture media may be buffered with phosphates to increase cell counts, but some cultures, particularly Lactobacillus bulgaricus appear to be inhibited by phosphates.

- Addition of phosphates also confers phage resistance because phosphates bind calcium, and phage require calcium to attach themselves to the bacterial cells.

- Calcium reduced skim milk powder and addition of anhydrous ammonia have also been used to inhibit phage in bulk cultures

- Culture media should be heated (at > 88ºC for 1 h) to destroy bacteria and some inhibitory substances. Heating also reduces the redox potential (lowers oxygen concentration) which encourages the growth of LAB.

- Optimum pH endpoint before cooling is between 4.5 and 5.5, depending on the acid tolerance of the culture. If the pH is too low, cell count will decrease during storage.

- Cell count can be increased by:

- Internal pH control using buffered media

- External pH control by adding sodium hydroxide or ammonium hydroxide to maintain pH at 5.0 ‑ 5.5.

- Optimum storage temperatures are 4ºC and 20ºC for mesophilic and thermophilic cultures, respectively. However, the optimum storage temperature depends on the particular culture. Consult with the culture supplier. Storage time should be as short as possible, but I am aware of plants that successfully use a single bulk set culture for a week or more before making a new batch.

5. Bacteriophage (Bacterial Viruses)

Like all viruses, bacteriophage (hence forth abbreviated to phage) are parasites. That is, part of their life cycle is dependent on the host bacteria. Here are a few facts about their characteristics and how they can be controlled.

- Extracellular phage called mature or resting particles are sperm shaped, < 1 micron in length, and consist entirely of DNA (genetic material) and protein. The basic structure is a DNA core enclosed in a protein sheath.

- The basic life cycle, called the lytic cycle, is:

- The resting phage attaches itself to the bacterial cell wall by its tail, bores a hole in the wall with the help of enzymes, and injects its DNA into the cell. The protein sheath remains outside the cell.

- From the moment of invasion the bacteria begins to reproduce phage DNA and protein in addition to its own.

- Nucleic acid and protein strands assemble themselves into new phage particles that eventually lyse the cell (break it open) to release the phage particles into the medium. A new generation of resting phage are now available to repeat the lytic cycle.

- Sometimes infection occurs without lysis resulting in a lysogenic culture where infected cells survive and reproduce infected daughter cells. Therefore, cheese cultures can exist in one of three states with respect to phage sensitivity:

- Insensitive due to inherent or acquired resistance.

- Phage carrier (lysogenic). In this state, the bacteria are resistant to another phage infection.

- Phage sensitive in which case the phage will grow quickly and may terminate the culture. Culture growth will stop when phage levels reach 103 to 107 per ml.

- Phage have a short latent period (reproduce as quickly as every 30 to 50 min) and a large burst size (each lysed cell will release 50 to 100 new phage).

- Phage are quite strain specific, which is the reason for culture rotation. As many as 10 different cultures may be rotated on a daily basis.

- Culture failure due to phage can be recognized by normal acid development initially followed by a decrease or termination of culture growth at a later stage. This is different than inhibition due to antibiotics, which can be recognized by no or slow initial growth; if inhibition is not severe, culture growth and acid development by resistant strains or mutants may increase with time.

Summary of Phage Control Measures

- Use aseptic techniques with proper culture room.

- Rotate cultures daily and/or use defined phage resistant strains.

- Use phage resistant media for culture preparation.

- Use direct‑to‑vat culture to avoid contamination during transfers.

- Use a mixed strain culture of two closely related strains.

- Remove and dispose of whey daily.

- Routinely check for presence of phage using a culture activity test with the culture currently in use and some whey from the most recent vat.

Note: The next scheduled course in the Cheese Maker Certificate Program is Dairy Fermentations. This course will expand on many of the topics discussed briefly here. The course will be of interest to anyone interested in cheese or other fermented dairy products. The principal instructor will be, Professor Martin Wilkinson, Science and Engineering, University of Limerick, Ireland.

Optical isomers are two compounds which contain the same number and kinds of atoms, and bonds (i.e., the connectivity between atoms is the same), and different spatial arrangements of the atoms, but which have non-superimposable mirror images, in the same way that your left glove does not fit on your right hand. Each non-superimposable mirror image structure is called an enantiomer. The left and right enantiomers are referred to as L and D, respectively. A dairy example is lactic acid. L-lactic acid tends to remain soluble in cheese but D- or blends of D- and L-lactic acid tend to form white crystals of calcium lactate on cheese surfaces.