Process and Quality Control Procedures

5 Compositional analysis

1. Total Solids

Oven Method

- Pre-dry aluminum dishes (105ºC, 1 h) and weigh to the nearest 0.1 mg on an analytical balance.

- Weigh quickly 3-5 g of fragmented cheese into the aluminum dish. The weight of sample is the total weight minus the weight of the dish from Step 1.

- Dry to constant weight (about 16 h) at 105ºC. To check for constant weight: weigh at least two samples, return both samples to the oven for an additional 20 minutes, and re-weigh. The difference between the weights before and after the additional drying period should be less than 1 mg.

- Cool in desiccator and determine total dry weight. Sample dry weight is the total dry weight less the weight of the dish determined in Step 1.

- Report total solids and moisture contents on weight percent basis as follows:

Application Notes

Accurate cheese moisture analysis is critical to composition and yield control. Rapid moisture tests (e.g., microwave moisture oven) can be used to obtain early feedback (e.g., cheese moisture immediately after pressing) information to help with process control. Several rapid moisture tests based on infrared or microwave drying are available. Check with your laboratory equipment supplier. Also, some infrared milk analyzers can be be calibrated to estimate total solids of cheese along with fat, protein and other parameters.

2. Babcock Methods for Milk Fat

The Babcock method, popular in North America, is based on disruption of the fat globule membrane with sulfuric acid. The Gerber Method, based on the same principle is more popular in Europe. Solvent extraction methods, namely, Mojonnier and Rose Gottlieb, are popular in North America and Europe, respectively, and are considered to be more accurate and precise than the sulfuric acid extraction. However, the sulfuric acid extraction is less expensive to set up and simpler to perform. In modern practice infrared analyzers (IR) are used for composition analysis of many foods. IR methods are rapid and accurate but have the limitation that they must be calibrated for each particular product. Accordingly, the Babcock and Gerber methods are still often used to estimate fat content of special samples. Also, smaller companies may still use sulfuric extraction to determine milk fat. Solvent extraction methods are still used as reference methods for calibration of infrared milk analyzers.

Apparatus and Materials

- Babcock centrifuge.

- Water bath at 55ºC.

- Torsion balance, 9 and 18 g weights.

- Babcock shaker.

- Glassware: 8% milk bottles, 50% cream bottles, 50% Paley bottles, 17.5 ml cylinders, 17.6 ml pipette.

- Reagents: Babcock sulphuric acid (Sp. Gr. 1.82 – 1.83), N-butyl alcohol, glymol

Milk

- Temper sample to 20ºC and mix by pouring gently from original container to a beaker of similar capacity 4 – 5 times.

A picture of a babcock bottle. - Transfer 17.6 ml (18.0 g) of milk to 8% bottle with 17.6 ml pipette. Allow pipette to drain then blow out the remaining drop into the bottle.

- Add 17.5 ml sulphuric acid (Sp. Gr. 1.82 – 1.83) in at least three increments using special cylinder. Rotate bottle between thumb and fingers while adding acid to wash milk from neck. Mix thoroughly 2 min after each addition of acid by moving the bulb of the bottle in rapid circular motion. Final colour of mixture should be chocolate brown.

- Centrifuge 5 min.

- Add distilled water at 60ºC to bring contents to within one-quarter inch of base of neck. Do not mix.

- Centrifuge 2 min.

- Add water at 60ºC to float fat into neck of bottle. Top meniscus should be about even with the top of the graduated portion. Do not mix.

- Centrifuge 1 min.

- Temper bottles in water bath at 55ºC for 5 min.

- Measure length of fat column with dividers from top of upper meniscus to bottom of lower meniscus. Place one divider point at zero mark and read percentage fat by weight directly where other point touches the scale.

Cream and Cheese

- Temper cream sample to 20ºC and mix. Grind cheese to small particles.

- Weigh 9 g of cream into 50% cream bottle and add 9 ml of distilled water at 20ºC. Weigh 9 g of cheese into a 50% Paley bottle and add 10 ml of distilled water at 60ºC.

- Add 17.5 ml sulphuric acid in at least three increments. Mix until colour is uniform chocolate brown and all cheese particles are dissolved.

- Centrifuge 5 min.

- Add distilled water at 60ºC to bring contents to within one-quarter inch of base of neck. Do not mix.

- Centrifuge 2 min.

- Add water at 60ºC to float fat into neck of bottle. Do not mix.

- Centrifuge 1 min.

- Temper bottles in water bath at 55ºC for 5 min.

- Place 4 – 5 drops glymol on the fat column letting these run down the side of the neck. Measure the length of the fat column from the demarcation between fat and glymol to the bottom of the lower meniscus.

- Report fat in percent by weight.

Skim Milk, Buttermilk, and Whey

- Temper sample to 20ºC and mix gently.

- Transfer 2 ml N-butyl alcohol and then a 9 ml sample to an 18 g double neck bottle. Mix thoroughly with a circular motion.

- Add 9 ml of Babcock sulfuric acid for skim milk or buttermilk, 7 ml for whey.

- Centrifuge 6 min. Place bottles in the centrifuge cup with the small neck facing the outside.

- Add water at 60ºC to bring contents 1 cm from the base of the neck. Do not mix. Centrifuge 2 min.

- Temper bottles in water bath at 55ºC for 5 min.

- Place a finger over the large neck and press down until the lower meniscus of fat in the small neck corresponds to a major division.

3. Cheese Salt

Cheese salt determination is traditionally done using the Volhard procedure[1]. Other methods which have proven to give accurate results are:

- Automatic Chloride Titraters operate on the principle of coulometric silver ion generation to titrate chloride ions in the sample. When all chloride ions are titrated, free silver ions cause a conductivity change which signals the end of titration.

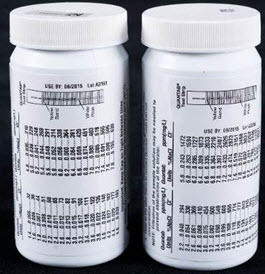

- Quantab Chloride Titrater depends on the reaction of chloride ions with silver dichromate, which is brown, to form silver chloride chromate ion and silver chloride, which is white. The reaction takes place on a calibrated strip which permits direct estimation of chloride content.

- Some infrared milk analysers can be calibrated to estimate salt content.

4. Inhibitory Subtances

- Most jurisdictions have regulations concerning the testing methods and limits of certain antibiotics in raw milk. The Milk Act of Ontario, Regulation 761, Section 52, Subsection, states:

- “The milk of every producer shall be tested at least once a month for the presence of an inhibitor by an official method.”It is recommended that cheese makers test all loads of milk for the presence of inhibitors. There are several adequate rapid and broad spectrum tests on the market. In Ontario, the Dairy Farmers of Ontario provides a small subsidy to processors to encourage tanker load testing before offloading the milk. The DFO also supports the industry via a document entitled Raw Milk Quality Program Policies, which is available at this link.

- Official Methods of Analysis of the Association of Official Agricultural Chemists, P.O. Box 540, Benjamin Franklin Station, Washington, D.C. ↵