Manufacturing, Ripening, Process Control and Grading

14 Ripening and Packaging

1. Ripening Processes: Biochemical and Biophysical Changes

Cheese ripening is basically about the breakdown of proteins, lipids, and carbohydrates (acids and sugars), a complex process that releases flavour compounds and modifies cheese texture. The biochemical and biophysical processes involved have only partly been elucidated. Here, we include only a few practical principles of ripening.

General Principles

- Ripening varies from nil for fresh cheese to 5 years or more for some hard ripened cheese. Like a good wine, a good aged cheese should get better and better with age.

- Ripening processes are broadly classified as interior and surface ripened.

- Varieties that depend mainly on interior ripening, such as Cheddar and Italian types, may be ripened with rind formation or may be film wrapped before curing. Having said that, I hasten to add, that traditional Italian types are always rind ripened. Traditional cloth bound Cheddar is also once again becoming more popular. American varieties are the only ripened cheeses that (in my view) are best ripened in film

- Cheese which depend mainly on surface ripening include smear ripened and mold ripened

- In the broadest terms, there are three sources of cheese flavour:

- Flavours present in the original cheese milk, such as natural butter fat flavour and feed flavour

- Breakdown products of milk proteins, fats and sugars that are released by microbial enzymes, enzymes endogenous to milk, and added enzymes

- Metabolites (various chemicals) produced by starter bacteria and other microorganisms

- Flavour and texture development are strongly dependent on:

- pH profile

- Composition

- Salting

- Temperature

- Humidity

- EXPERIENCE

- As a general rule, factors which increase the rate of ripening increase the risk of off flavour development, and reduce the period of time when the cheese is saleable.

- Some off flavours associated with undesirable or excessive protein breakdown in cheese are bitter, stringent, putrid, and brothy.

- Protein breakdown causes shorter body that is less rubbery, less elastic, and more meltable. For example, flavour and texture development in Cheddar are mainly dependent on protein breakdown and much less dependent on fat breakdown.

- Protein breakdown involves three general types of processes:

- Proteases break proteins into smaller peptides, some of which are flavour compounds. For example, bitter and brothy flavoured peptides are well known to occur in cheese.

- Peptidases further break down peptides to amino acids.

- Further catabolism of amino acids by cheese microorganisms produces aldehydes, alcohols, carboxylic acids, and sulphur compounds, many of which are flavorful.

Many aged cheeses containing large crystals of calcium salts of tyrosine.

- Many aged cheeses contain crystals of calcium salts of tyrosine. Tyrosine is an amino acid resulting from protein breakdown. The crystals may be quite large (up to 2 mm) and are easily detected on the pallet.

Fat Breakdown (Lipolysis)

Dairy fat is a rich source of flavours, because it contains an extremely diverse selection of fatty acids. In particular, butter fat is the only natural fat which is rich in short chain fatty acids. Butyric acid for example is a potent flavour compound. As with all potent flavours, the trick is to deliver just the right amounts in balance with other flavours. Here are a few principles:

- Dairy fat without any ripening during cheese making is an important contributor to cheese texture and flavour. Fresh dairy fat has the well-known ‘buttery’ flavour associated with low levels of free fatty acids.

- Fat is an important component of cheese softening and melting.

- The fat derived flavours associated with cheese ripening result from the release of fatty acids by lipolysis and further modification of fatty acids by microorganisms to other compounds.

- Varieties traditionally made from goat milk have higher levels of lipolysis, especially if made from raw milk, because goat milk, relative to cow milk, has much higher levels of lipoprotein lipase (LPL). However, LPL, is mostly inactivated by pasteurization.

- Blue molds are generally quite lipolytic.

Lactose

Milk contains no starch or fibre or any sugar other than lactose, so all carbohydrate compounds in cheese are derived from lactose or produced by microorganisms. Relative to fat and protein, lactose contributions to flavour are minimal. Here are several principles:

- At Day 1 following cheese manufacture, most of the milk sugar has been removed in the whey or converted to lactic acid by the cultures.

- Residual lactose depends on the type of cheese and other factors. For examples:

- High salt in the moisture phase of Cheddar slows lactose metabolism so lactose content is 0.3 – 0.7% at one day after manufacture and slowly declines to less than 0.1% during curing.

- Residual lactose in Camembert cheese is used by Penicillium camemberti, so it decreases quickly, especially on the surface, when the mold begins to grow.

- In well drained cheese such as Swiss types, lactose is completely used up in a few hours.

- In washed cheese varieties, lactose not leached by washing is quickly used up by the culture, especially for brine salted cheese where salt takes more time to move into the cheese.

- In American varieties, early vat salting reduces the rate of utilization of residual lactose.

- Many organisms, including yeasts and molds, in mold and smear ripened cheeses utilize lactic acid and produce various flavourful compounds.

- Calcium salts of lactic acid may form white precipitates on the surface of aged cheese.

Cheese showing calcium precipitates on the edges.

2. Principal Ripening Agents

Milk Enzymes

- Plasmin: a native milk protease which survives pasteurization and breaks down all caseins, but beta-casein more than the others.

- Particularly important in Swiss type cheese.

- Inhibited by Beta-lactoglobulin, so it has minimal activity in cheese made from ultrafiltered milk, where there is an abundant amount of whey proteins.

- Lipoprotein lipase: the principal milk lipase

- Inactivated by low heat treatment but is important to flavour development in raw milk cheese. In some cases, commercial lipase is added to develop cheese flavours.

Milk Coagulant

The principal types of rennet used to coagulate milk for cheese making are described in Chapter 18, where we noted that commercial rennet includes pure calf rennet (chymosin), Recombinant rennet which is identical to chymosin, and rennet-like enzymes produced by molds. All of these enzymes belong to a family of aspartic proteases, which readily cleave k-casein between protein residues 104 and 105. However, as noted in Chapter 13, these enzymes also contribute in different ways to breakdown of other proteins:

- Each milk coagulant has its own proteolytic profile.

- Purified rennet extracts and recombinant chymosin (also quite pure) reproduce more consistent flavours.

- Rennet and recombinant rennet actively break down alpha-casein, but do not break down beta-casein in cheese.

Lactic Cultures

- During the early days and weeks of ripening, LAB numbers decrease while the numbers of nonstarter bacteria increase. For example, in Cheddar cheese, LAB counts reach a maximum (up to 500 million per gram) within 3 – 4 days and then decrease to about 20 million at 4 weeks. However, the dying cells release enzymes that continue to ripen the cheese.

- Thermoduric (non-spore forming bacteria that survive pasteurization), and spore forming bacterial species of genera Bacillus and Paenibacillus

- Lactic cultures contribute to proteolysed flavours but are minimally lipolytic.

- Heterofermentative cultures ferment citrate as well as lactose and contribute both flavour (diacetyl) and carbon dioxide for small eye development.

Secondary Cultures

- In Swiss types, carbon dioxide production by Propionibacterium is encouraged by exposure to 20ºC for about 3 weeks after brining and drying off in the cold room.

- For smear ripened cheese, Brevibacterium linens, coryneform bacteria, and yeasts are encouraged by high humidity (90 – 95%) and washing to discourage molds.

- Penicillium sp. for Camembert, Brie, and Blue types require 85 – 90% humidity and air circulation to provide oxygen.

Non-Starter Microorganisms

Microorganisms present in the milk due to environmental contamination are important contributors to cheese ripening. Some important principles are:

- Bulk cooling and storage of raw milk selects for cold tolerant (psychrotrophic) bacteria (see Chapter 3).

- Non-starter bacteria commonly present in heat-treated Cheddar include Lactobacillus sp. and Pediococci sp.

- Many other bacteria and yeasts may be present and may or may not grow depending on complex symbiotic relationships with other bacteria.

- Heat treatment of milk as described in Chapter 5, selects for thermoduric bacteria. In effect, heating is used to standardize the nonstarter microorganisms. Important results, particularly for sub-pasteurization heat treatments, are reduced numbers of proteolytic psychrotrophic bacteria and retention of a range of useful microbial ripening agents.

- Non-starter bacteria in cheese milk can be reduced by microfiltration. This is common practice for low fat cheese.

Added Ripening Agents

Ripening agents are used mainly to accelerate ripening of traditional varieties and to improve the quality of reduced fat varieties. Cheddar, including low fat Cheddar, is the focus for much of the ongoing work in this area. The principal approaches are:

- Direct addition of single enzymes of dairy or non-dairy sources.

- Enzyme cocktails which are mixtures of proteases and lipases. Other than in the preparation of enzyme modified cheese pastes, enzyme cocktails have had limited commercial success.

- Enzyme capsules which release trapped enzymes during ripening.

- Attenuated (freeze shocked or heat shocked) proteolytic cultures.

- Genetically modified cultures.

- Culture adjuncts such as Lactobacillus helveticus in Cheddar cheese (See Section 7.5).

3. Cheese Composition for Optimal Curing

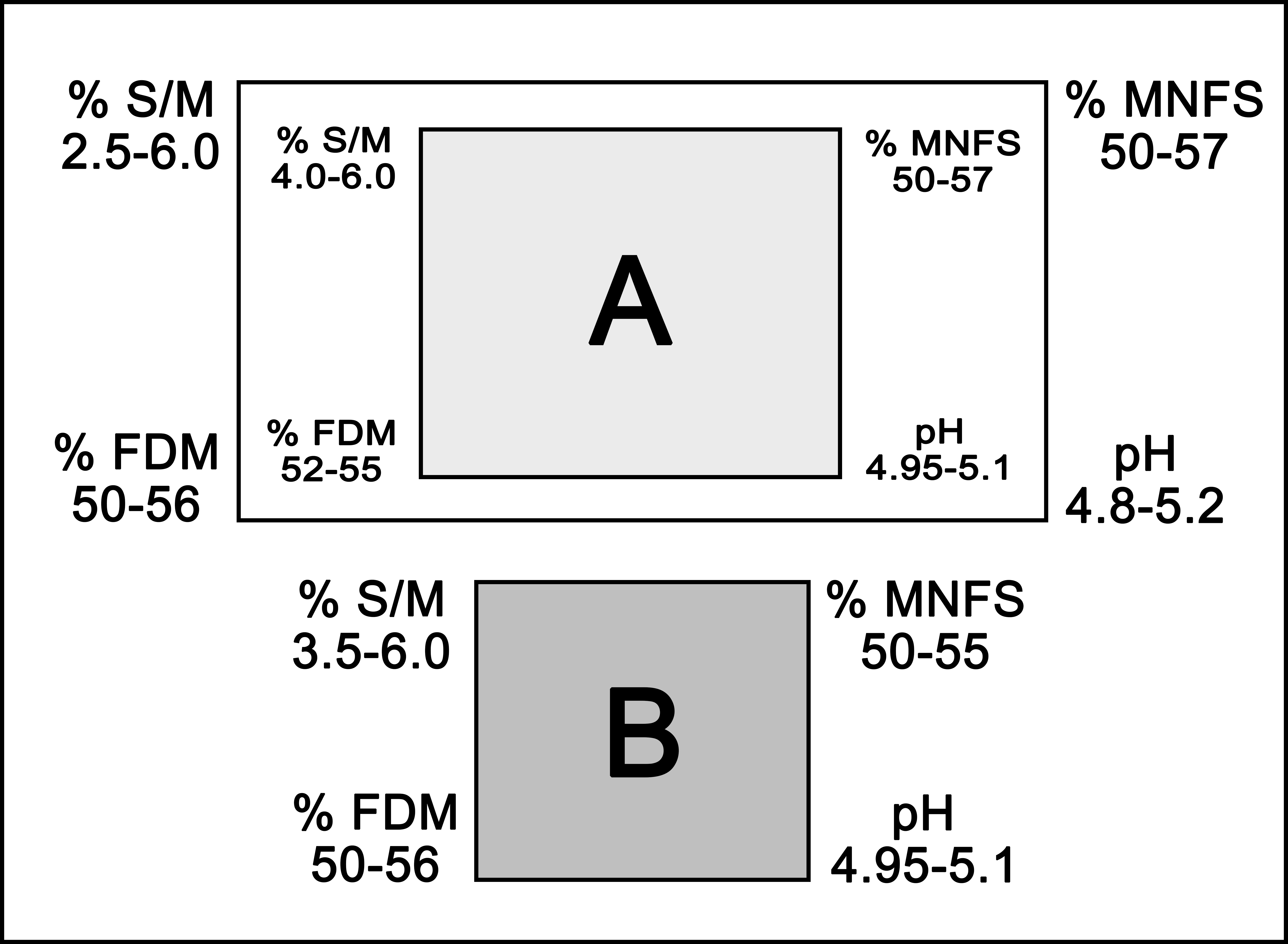

Cheese composition is critical to yield optimization, and both flavour and texture development. This section describes several critical composition parameters, with special reference to Cheddar cheese. As indicated in Figure 10.1 (A), New Zealand has composition standards for Cheddar cheese. Figure 10.1 (B) indicates the ranges, which in my view are typical of good Canadian Cheddar. Each of these composition parameters are described below.

Note: pH is measured between 3 and 14 days after manufacture.

MNFS (Cheese Moisture as a Percentage of The Non-fat Substance)

- Moisture: higher moisture cheese ripens faster, which means more potential for off flavours and over ripening.

- Water activity (aw) decreases with age because ripening results in many soluble breakdown products of acids, sugars, proteins, and lipids.

- Fresh Cheddar aw = 0.98, which is conducive for growth of most bacteria.

- In aged Cheddar, aw may be as low as 0.88, which is too low for growth of most bacteria.

- MNFS is a better index of cheese ripening potential than % moisture.

- Optimum MNFS depends on expected date of maturity and curing temperatures.

- MNFS is controlled mainly by pH at draining and cooking treatments. Subsequent curd treatment, such as curd ripening and salting, also influence MNFS.

- MNFS is also influenced by FDM (percent fat in the dry matter of cheese). Other conditions being constant, MNFS increases with increasing FDM, because fat inhibits syneresis.

SM (Salt as a Percentage of Cheese Moisture)

- Determines rate of acid development during pressing and early curing and, therefore, influences the minimum pH.

- Affects bacterial profile, e.g., high SM will discourage contaminating bacteria such as coliforms.

- Influences the rate of proteolysis and the type of protein derived flavours.

- Fortunately, the acceptable range is broad (3.6 ‑ 6.0), because SM varies widely even within a single cheese.

- Salt uptake is affected by quantity of added salt, size of curds, moisture content of curds, and acidity.

- When the salt content exceeds two percent of the total weight of the cheese consumers tend to perceive the cheese as too salty. For typical Cheddar of 37% moisture two percent salt corresponds to 5.4% SM.

FDM (Cheese Fat as a Percentage of Dry Matter or Solids)

- Higher fat restricts syneresis, so MNFS tends to increase with FDM.

- Fat shortens and softens cheese texture because the fat globules physically disrupt the protein matrix.

- FDM is determined by milk PF (See Chapter 5).

pH

- The pH profile is the single most important trouble-shooting tool. Critical points are: cutting, draining, milling, forming, 1 day and 7 days.

- Most predominantly rennet coagulated cheese with some exceptions, should reach a minimum pH of 5.0 – 5.3 during the first week after manufacture. Obtaining a final pH in this range is greatly helped by increased buffer capacity of milk proteins in the pH range 5.2 – 4.6.

- Factors determining the pH at 1 day are amount of culture, draining pH, washing, curd treatment such as curd ripening, and salting.

- Draining pH is most important to cheese texture and also determines residual amounts of chymosin and plasmin in the cheese.

- pH increases with age due to release of alkaline protein fragments. This is especially true of mold ripened cheeses. The pH of Camembert increases from a pH of 4.6 to a pH of 7.0, especially on the surface.

- Increasing pH during curing encourages activity of both proteases and lipases.

4. Temperature of Curing

- Cheddar types: it is desirable to initiate ripening for several weeks at 4 – 6ºC and then increase the temperature to 8 – 10ºC. Low temperature initially, minimizes early growth of starter and non-starter bacteria and reduces the risk of off flavour development. It also minimizes the risk of the minimum pH reaching levels below 5.0.

- Most firm to hard varieties are ripened at 10 – 15ºC and then stored at about 4ºC until consumed.

- Most surface ripened varieties are ripened at 12 – 15ºC and then stored at about 4ºC until consumed.

5. Humidity of Curing

Surface ripened cheeses also require adequate air circulation to provide sufficient oxygen for molds and yeasts. Humidity requirements in general are:

- Washed bacterial surface ripened: 90 – 95%

- Fungal flora: 85 – 90%

- Dry rinds: 80 – 85%

6. Ripening Treatments

Surface treatments for cheese ripening can grouped as follows:

- Ripened by surface molds.

- Washed rinds with minimal bacterial growth, e.g., St. Paulin types.

- Washed rinds with smear, e.g., Muenster types and Oka.

- Washed rinds with mixed flora including molds and bacteria.

- Dry rinds that may be coated with oil or butter to prevent cracking and desiccation, e.g., some hard Swiss and Italian types.

- Cloth bound. Traditional Cheddar was cloth bound, and some still is.

- Sealed surface. Most commercial Cheddar was formerly sealed in a paraffin wrap for ripening until the ’70s when plastic films became common. Also large blocks of Cheddar (up to 640 lbs or 290 Kg) can be sealed and ripened in large plastic forms.

-

Cloth-bound cheddar. Waxes, resins, and edible coatings may be applied by dipping, brushing or spraying and may be treated with pimaricin, sorbic acid or propionates to prevent mold growth. These typically provide good protection but are more permeable than plastic films, so it is still desirable to maintain 85% RH to prevent drying and regularly clean the surfaces.

- Rindless cheese which are cured in moisture and gas impermeable film or in large blocks (e.g., 640lb Cheddar)

7. Packaging

- Vacuum and/or gas flush (N² and CO²) in gas and moisture proof film are common.

- Vacuum alone is not recommended because complete evacuation of oxygen is difficult and small unsightly mold spots often appear.

- Gas flush with CO² or blends of CO² and N² effectively prevent mold growth.

- CO² is water soluble so it is absorbed into the water of the cheese and the package becomes tight.

- N², which is not water soluble, is useful for applications such as shredded cheese and cheese curd where a loose package is desired.

- High density plastic (rigid) containers are used for fresh cheese such as cottage.

- Oxygen permeable wrap such as grease proof paper and foil-laminated but unsealed wraps, are preferred for surface ripened soft cheese.

- Firm to hard cheese with dry rinds or coated rinds may be transported and offered for sale with no further packaging.

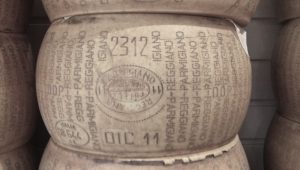

A wheel of Parmigiano Raggiano, an Italian PDO hard cheese from Parma.

A substance that is able to speed up reactions in organisms.

The process of breaking up and rejoining genetic material. In this case, the chymosin gene is taken out from the cow genome and placed in a plasmid, which is piece of DNA that is able to replicate independently. The plasmid is then inserted into a microorganism which starts to produce chymosin. Chymosin is produced by transcribing and translating the chymosin genetic code in the plasmid.