Manufacturing, Ripening, Process Control and Grading

13 Cheese Making Step-by-Step

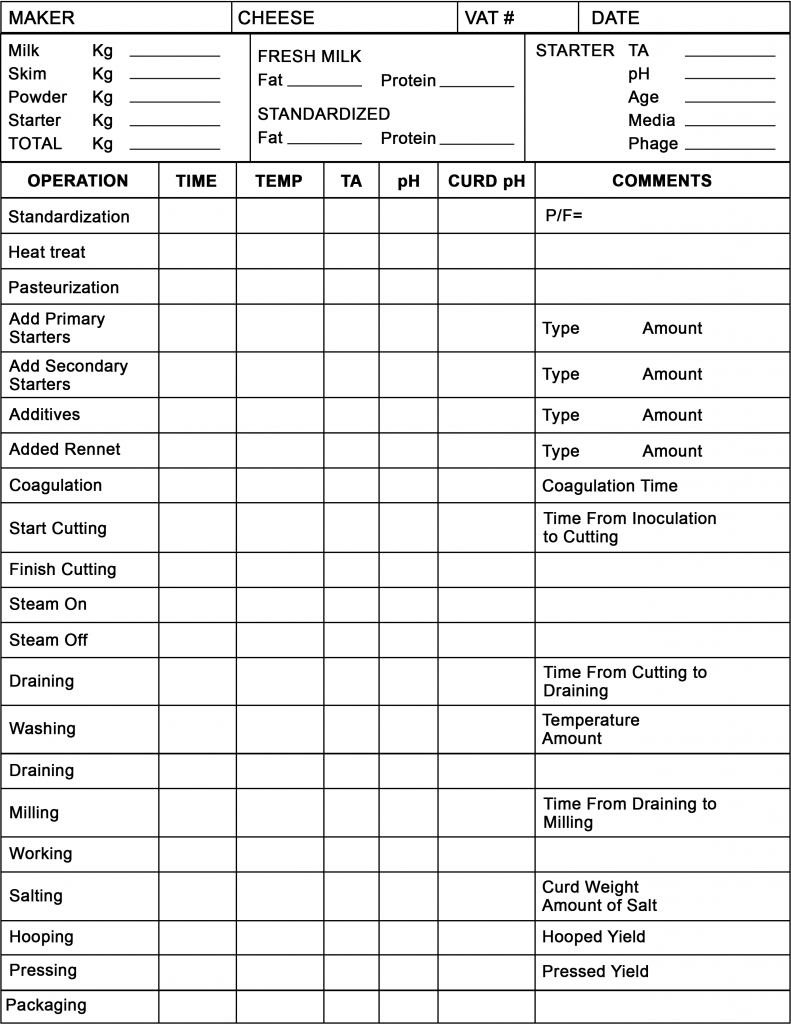

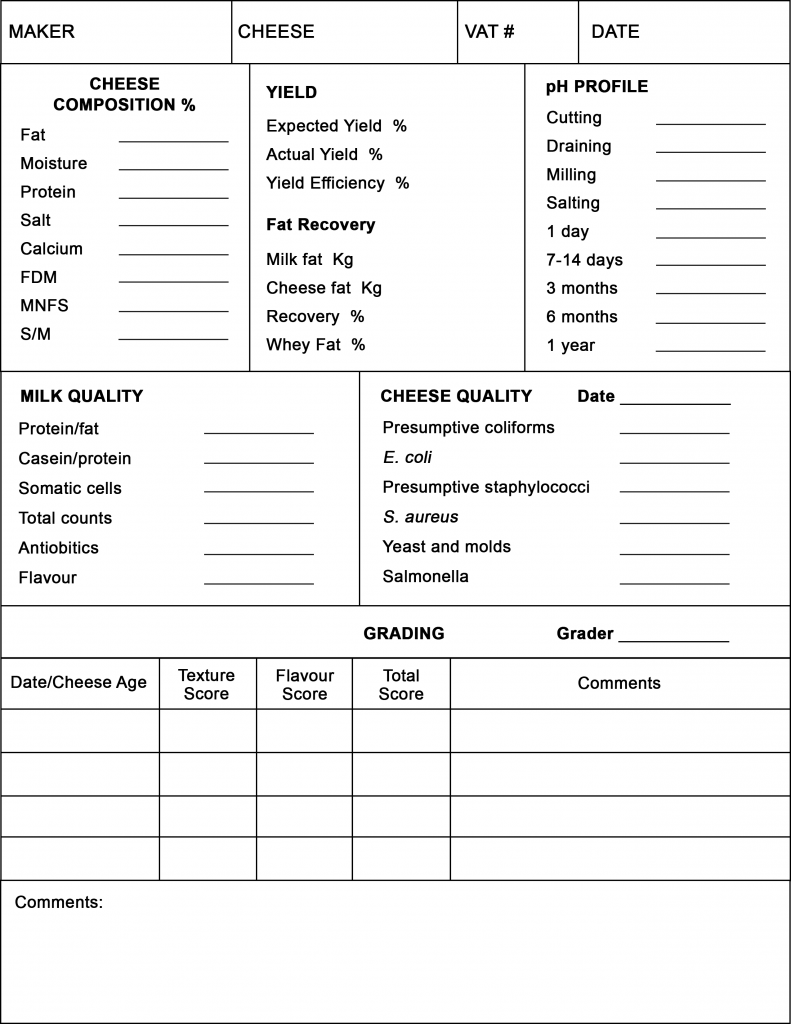

This chapter describes the principal steps involved in cheese manufacture. Figures 13.1 and 13.2 at the end of the unit are sample process (make) and quality sheets.

1. Ripening the Milk

This term is a little confusing because it is also used to describe the ripening or aging of cheese. Here, ripening refers to the practice of giving the culture time to begin acid production before the rennet is added. This is done for two reasons:

- To ensure the culture is active before the milk is renneted. It is impossible to inoculate after the milk is set. Normally, 45 – 60 min is sufficient to increase TA (titratable acidity) by 0.005 – 0.01%.

- Development of acidity aids the coagulation process, especially the secondary stage.

In many varieties such as Brine Brick and Swiss, low amounts of culture are used and renneting proceeds with little or no prior production of lactic acid.

2. Setting the Vat

Handling Rennet

- Repeatable performance depends on accurate measurement. For most varieties, the quantity of rennet is selected to set the milk to a firm coagulum in 30 – 40 min, corresponding to about 50 IMCU per liter. Measure the rennet accurately and monitor to ensure that coagulation rate is uniform from day to day.

- Rennet must be diluted (about 20 times) in water and well mixed when added to ensure uniform distribution.

- Watch out for chlorine. It is imperative that the dilution water contains no chlorine. Two ppm of chlorine will destroy 40% of rennet activity in 3 minutes. Similarly, do not sanitize the container used for the rennet with chlorine.

- Another water quality issue is pH. Typically, if the water is hard, it also has pH greater than 7.0, which also decreases rennet activity.

- Finally, dilute the rennet not more than 30 minutes before adding to the vat. After the brined rennet is diluted in water, its activity declines.

Optimizing Setting Parameters

- Milk preparation was discussed in Parts 10 and 11. Here are the principal considerations:

- Pasteurization temperature: higher temperatures increase yield by increased recovery of whey proteins, but a suggested maximum with respect to curd quality is 75ºC, 16 s.

- Temperature history: if the milk is pasteurized and immediately sent to the setting vat, it will be necessary to adjust the mineral balance by adding calcium chloride.

- The jury on selection of coagulant always seems to be out. If microbial coagulants are to be used for high temperature varieties, ensure that the supplier certifies that the heat treatment in the cheese making process is sufficient to substantially reduce the activity of the enzyme. For other varieties, the caution is to ensure that yield and flavour development are not compromised. Given the decreasing availability of calf rennet (the technical name for calf rennet is chymosin), recombinant rennet is the preferred enzyme provided that customers are not spooked by the genetic technology.

- The amount of rennet must be carefully determined. Because rennet is costly, it is desirable to minimize its use, but this can be false economy if curd properties or cheese quality are compromised. Poor setting means increased losses of both fat and protein as fines. And, don’t forget that the coagulant is also a ripening agent.

- Temperature control must be accurate and uniform throughout the vat because both the enzyme activity and the subsequent process of micelle aggregation are extremely temperature sensitive. Inaccurate or non-uniform temperature during setting will result in local areas of under or over set curd, which in turn cause loss of fines during cutting.

- Soft curd results from:

- Over heat treatment

- Low setting temperature

- Colostrum or mastitic milk

- Firm curd results from:

- High calcium

- Low pH

- Standardization to high protein content

3. Cutting the Curd

Proper cutting is important to both quality and yield. Improper cutting and handling the curd results in the loss of fines; that is, small curd particles which are not recovered in the cheese. Unlike whey fat, fat trapped in fines is not recovered by whey cream separation. Therefore, both fat and protein losses occur when shattered curd results in fines too small to be recovered in the cheese.

Determination of Curd Cutting Time

Both early cutting when the curd is fragile and late cutting when the curd is brittle cause losses of fines. Several means are used to determine cutting time.

- Manual testing. The curd is ready to cut if it breaks cleanly when a flat blade is inserted at a 45º angle to the surface and then raised slowly.

- Several mechanical devices based on oscillating viscometry, thermal conductance, or sonication have been tested experimentally and some are used in commercial practice.

- Some plants cut by the clock. This may be OK as long as all conditions are uniform from day to day (is that ever true?) and adjustments are made for any change in milk composition or properties.

- If setting temperature is high, as for some Swiss recipes, the curd firms rapidly and cutting must begin early when curd is still somewhat soft to prevent over setting. Agitation should begin immediately to prevent matting.

Curd Size

Curd size has a great influence on moisture retention.

- High temperature and low moisture varieties such as Italian hard cheese require the smallest curd. Cutting continues until the curd is the size of rice grains.

- Medium moisture cheeses like most washed varieties and Cheddar are cut to ½ cm cubes.

- High moisture varieties like soft ripened cheese are cut with 2 cm knives or the curd is simply broken sufficiently to be dipped into forms.

Small curd size will result in greater fat and NFS recovery because large curds tend to get crushed, resulting in the loss of “fines.” Smaller curds will also dry out faster and, therefore, other factors such as cooking temperature and stirring out may have to be adjusted according to curd size.

Manual Cutting

Manual cutting is done with cutting harps, made by stretching stainless steel or nylon wire over a stainless steel frame. Total cutting time should not exceed 10 minutes (preferably less than 5 minutes) because the curd is continually changing (becoming overset) during cutting. The knives should be pulled quickly through the curd so they cut the curd cleanly, rather than push it around the vat.

Automated Cutting

With mechanical knives, the curd size is determined by the design of the vat and agitators, the speed of cutting (rpm) and the duration of cutting. In Double ‘O’ vats for Cheddar and American varieties, cutting is normally at a speed of about 4 rpm for 7 – 13 minutes, corresponding to a total of 30 – 50 revolutions. It is important that the knives are sharp, so they cut the curd cleanly rather than partially mashing the curd or missing some pieces altogether.

There is evidence[1] that curd particle size at draining in mechanized Cheddar cheese is influenced by cutting time, cutting speed, and subsequent agitation such that:

- Short cutting times and low rpm result in small particle size at draining and more loss of fines.

- With increasing cutting time (more total revolutions), curd particle size at draining reaches a maximum which corresponds to a maximum in fat recovery.

- Further increased cutting time causes decreased curd size at draining with little effect on fat recovery.

Healing

The exterior of the freshly cut curd is fragile, so some time is needed for the surfaces to close up (heal) and prevent the loss of fat and protein in the whey. Fresh cut curd also has a tendency to aggregate, which is undesirable. So, agitation after cutting should be minimal to give the curd some time to heal, but sufficient to prevent the curd from matting.

An Index of Cutting Quality

The loss of fines is best monitored by accurate analysis of whey fat content. Whey fat for cheese with 50% FDM should be < 0.3%. Efficient operations may achieve levels near 0.2%.

4. Cooking

The combination of heat and the developing acidity (decreasing pH) causes syneresis with resulting expulsion of moisture, lactose, acid, soluble minerals and salts, and whey proteins. It is important to follow the cooking schedule. Cooking too quickly forms a tough exterior on the curd particles which prevents moisture release and hinders development of a smooth texture during pressing.

5. Draining

The whey pH at draining or dipping is less than 5.0 for predominantly acid coagulated varieties and 6.1 – 6.4 for many predominantly rennet coagulated varieties. The exceptions are varieties with no or little culture (see Chapter 2). Draining time should be uniform at about 20 min to prevent variation from vat to vat. Cheddar types may be stirred out 1 – 3 times as required to obtain required curd moisture.

6. Washing

Lactose content can be adjusted by moisture removal (syneresis), fermentation, or leaching with water (washing). Washing to remove lactose makes it possible to make a high moisture cheese and still achieve a final pH of about 5.0 – 5.2. Most cultured varieties with final moisture higher than 40% and minimum pH greater than 5.0 are washed. Temperature of the wash water will determine the moisture content of the curd. Sometimes relatively hot water (e.g., Gouda) is used to dry the curd and develop its texture.

Traditionally, washing was accomplished by removing 50 to 65% of the whey, replacing it with water, and agitating for about 15 min. This process results in the dilution of large amounts of whey that must be concentrated or dumped. It also creates problems where curd tables have less capacity than setting vats. The solution is to remove more whey before washing and reduce the amount of wash water. In American style varieties such as Colby and Monterey Jack, the whey is removed almost completely and washing is accomplished by spraying water on the curd while agitating the curd with forking agitators.

7. Curd handling

Procedures applied during and after draining are many and varied. However, most post draining procedures are similar to one of the following.

Dipping: Dipping is often used as another term for draining, but it applies in particular to cheese varieties for which curd and whey are “dipped” into forms. There may be a “pre-draw” to drain some whey from the curd before the remaining whey is dipped with the curd into the forms. Whey drainage takes place in the forms, which are turned frequently to enhance drainage and ensure uniform shape and smooth surfaces. Soft ripened varieties and most smear (washed rind) varieties are dipped. In modern practice, the curd is partially drained and then pumped into the forms with positive lobed pumps, which do not crush or otherwise damage the curds.

The process of dipping encourages formation of mechanical openings. Mechanical openings result when whey trapped inside the curd is absorbed into the cheese and leaving irregularly shaped holes behind. Much of the open structure in Havarti, for example, is due to mechanical openings.

Consolidated or Pressed Under The Whey: Cheese with small eyes (Dutch varieties), larger eyes (Swiss and related types), and cooked Italian varieties are consolidated under the whey or even pressed under the whey. For example, for traditional Swiss types, French Comté, and Parmigiano, the curd is gathered together under the whey in a large cloth and transferred directly to the forms prior to pressing.

For Gouda and more mechanized versions of Swiss types, it is common to press the curd under the whey using “curd tables” or “press vats” designed for that purpose. Allowing the curd to fuse under the hot whey prevents mechanical openings and helps develop smooth elastic texture, which is ideal for eye formation. The curd is then transferred into hoops for pressing.

Vat Salted Varieties: Cheshire and Cheddar and their cousins and derivatives are handled in different ways after draining, but have this in common that salt is added before the cheese is formed and pressed. The resulting structure of the cheese is coarser (less fused) relative to cheese that is consolidated under the whey and less open than cheese that is dipped into the forms.

Most Latin American rennet coagulated fresh cheese varieties such as Panela, are also salted before pressing (see Chapter 2).

Pasta Filata Varieties: (Italy) and similar stretched cheeses incorporate a curd ripening step similar to Cheddar followed by milling to form small curds that are fused together and kneaded and stretched in hot water to create a fibrous structure. In mechanical operations the curd is kneaded by augers and forced up a rectangular tube of decreasing size. This causes the curd to stretch and fuse together creating typical fibrous structure.

8. Pressing

Pressing varies from little or none for soft cheese up to 1.5 kg/cm2 (21.3 p.s.i) for firm or hard cheeses. Warmer curd or curd with higher fat requires less pressure. Pressing also depends on the size and shape of the form. For example in a large mould, the force (numerator) of the press is distributed over a larger area (denominator). Mechanical openings may be reduced by vacuum treatment before, during, or after pressing.

9. Salting

Almost all cheese is salted by one of three methods: before pressing, as in Cheddar and American varieties, surface salting after pressing, or brine salting.

Purposes of Salting

- Promote further syneresis

- Slow acid development

- Check spoilage bacteria. LAB are more salt tolerant than many pathogenic and spoilage bacteria

- Promote controlled ripening and flavour development

- Salty flavour

Brine Salting

Salt concentration in cheese brines is in the range of 16 – 25% NaCl, but typically 20 – 23%. At brining temperatures (less than 10°C), the saturation point for salt in water is about 26%.

New brine should be treated with about 0.1% of CaCl2 to prevent conversion of calcium and hydrogen caseinate to sodium caseinate. The latter has high water holding capacity, so the cheese takes up water from the brine and the cheese surface becomes soft and slimy. Also, brine pH should be adjusted to the pH of the cheese. Normally a pH of 5.2 – 5.6 is adequate. If the pH is too high, ion exchange causing sodium caseinate is encouraged. If the pH is too low, there is insufficient Ca/Na exchange and the cheese surface becomes hard. A suggested recipe [2] for 100 Kg of brine is:

- 30 Kg salt

- 80 Kg water

- 170 mL of 30% Calcium chloride solution

- 50 mL of vinegar (5% acetic acid) or 10 mL of lactic acid

Brining time is dependent on the shape and weight of the cheese. A rule of thumb suggested by Kindstedt (2005) is:

1 h per 0.9 Kg per cm OR 1 h per pound per inch.

For example, a 1 Kg cheese made in a Kadova mold such as we have in the Guelph pilot plant is about 7.5 cm thick. So, the estimated brining time is 0.9 x 7.5 = 6.7 h. It is important to monitor the brine with a salometer and adjust as necessary to maintain the target brine concentration. Also, monitor salt concentration in the cheese to ensure that it’s consistent and close to the target level.

Brine must be continuously agitated to prevent density fractionation (lower concentration brine on top) and dilution of the brine around the cheese. Brine must also be cleaned regularly by micro- or nanofiltration. Nanofiltration has the advantage that in addition to removing bacteria and proteins, it also removes smaller molecules such as residual sugars, but it does not remove salt. Sometimes UV sterilization is combined with filtration to further reduce the chance of contamination.

If cheese is floated rather than immersed in the brine, the exposed surface of the cheese should be dry salted.

Vat Salting

- For vat salted cheese, uniform salt content depends on accurate estimate of the weight of unsalted curd, accurate weighing of salt, and consistent processing conditions

- Salt uptake is:

- Increased by increased acidity (lower pH) at salting

- Decreased by increased time between milling and salting due to healing of the cut surfaces on the curd particles

- Increased by increased curd moisture content

- Decreased for larger curds

- For Cheddar and American varieties, the salt content as a percent of moisture (SM) should be greater than 3.6%

The act of cheese curds sticking together after cutting the curd.